Pitch and yaw drive systems for wind turbines

High-performing drive solutions in all operation states

Intelligent and safe drive solutions for pitch and yaw applications

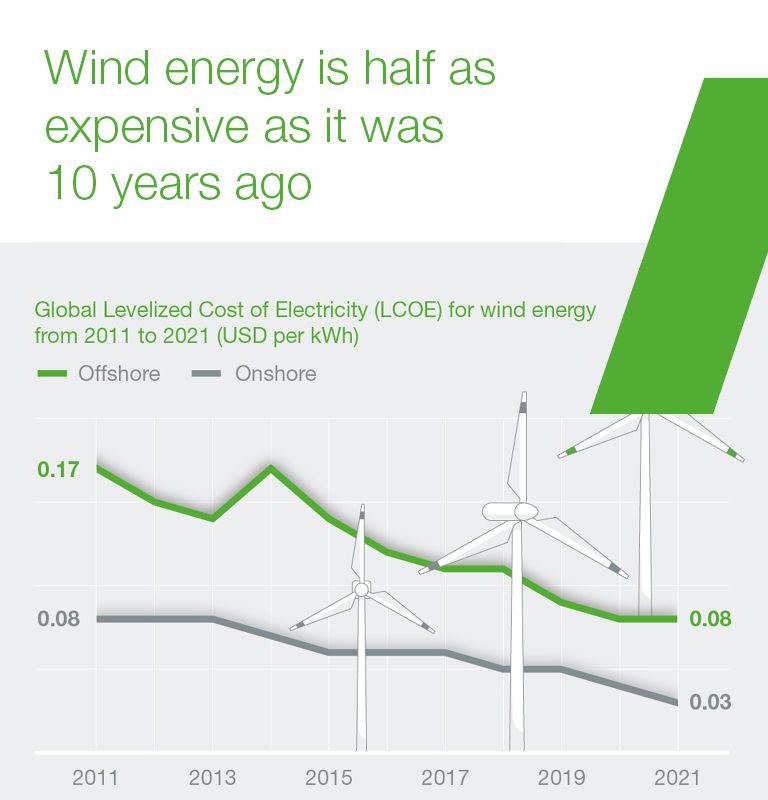

The demand for lowering of levelized cost of electricity (LCoE) in the wind energy sector calls for cost-efficient, robust drive solutions and functionally safe products to further increase the availability and safety of wind energy.

KEBA offers many years of experience and a variety of references around electromechanical drive systems for onshore and offshore wind turbine installations.

Your benefits at a glance

- Close to 25 years of application expertise

- Cost-efficiency and flexibility for your preferred system architecture

- Functional safety reduces material input

- Lower plant operating costs

Solution portfolio for your turbine platform

In order to achieve the optimal design of a wind turbine installation, a wide array of legal requirements, standards, and practices must be combined.

A large portion of these relate to the pitch system and the yaw drive system.

KEBA provides advice for the design of your pitch and yaw motors as well as the associated drive controllers, based on your load specifications.

The latest developments in power provision and comprehensive TÜV-certified safety features for simulation-based testing help our customers in the validation process and thus ensure an effective life cycle management of the wind turbines.

Subsequently, this can also be used for slimming down the structural components from the blade tip to the foundation. This opens up great savings potential.

Whether you need troubleshooting support during commissioning or during normal operation of the plant, you can always draw on the know-how of our experts.

For repairs, spare parts or retrofitting operations, our skilled personnel provide competent advice and best-in-class support.

Pitch systems, yaw drives and more

Modern wind turbines are highly complex machines. Developing, operating, and sustaining such installations requires highly specialized know-how. The KEBA team of experts can draw on decades of experience and up-to-date training for the challenges to come. Our knowledgeable team is happy to assist with your needs in the areas of pitch control systems, Yaw drive systems and aftermarket services.

Pitch control systems

Our team has many years of experience in the development of Pitch control systems. We assist you with designing your system and help you find a cutting-edge, cost-optimized solution.

Our solutions:

- Drive design

- Safety concept in the Pitch system

- Storage sizing

Yaw drive

The demand for lower wind turbine costs and LCoE extends to yaw drive applications, too. Conventional concepts with motors running directly on the grid involve certain technological drawbacks.

Unwanted loads due to abrupt start-up operations increase mechanical wear and tear. In addition, the electrical and hydraulic systems need to harmonize.

These problems can be addressed through the use of a controlled multi-axis drive system that synchronizes and optimizes the drive output power of the individual motors. KEBA’s modular KeDrive D3 system supports this approach using state-of-the-art servo drive technology.

Aftermarket

Aftermarket products and services play a major role in our customer service offering. For service providers, KEBA offers quick, easy, and competent support for repairs and the procurement of spare parts and helps you select the right components for retrofit operations.

This ensures that defective wind turbines can be brought back online quickly.

Take advantage of our know-how! We look forward to receiving your inquiry.

Ease of maintenance

Reduced number of components

The Pitch drives include a PWM voltage brake driver for the direct actuation of the motor brake. Like the built-in backup power charger, this further reduces the number of components in the cabinet and maximizes availability and ease of maintenance.

This might also interest you

PitchMaster II+

The PitchMaster II+ products have been designed for the rugged external conditions in the rotating hub of a wind turbine installation.

PitchOne

Find out about the innovative features and benefits of the trailblazing new PitchOne servo drives for your wind turbine installation.

Drives solutions for wind turbines

Frequently asked questions about KEBA´s product offering can be found in our blog article.

Thank you for your request. Our KEBA Customer Support will get in touch with you soon.

Locations

Business Areas

Newsroom

Edge

Chrome

Safari

Firefox