Magnetic bearings

Premium bearing technology for high speeds

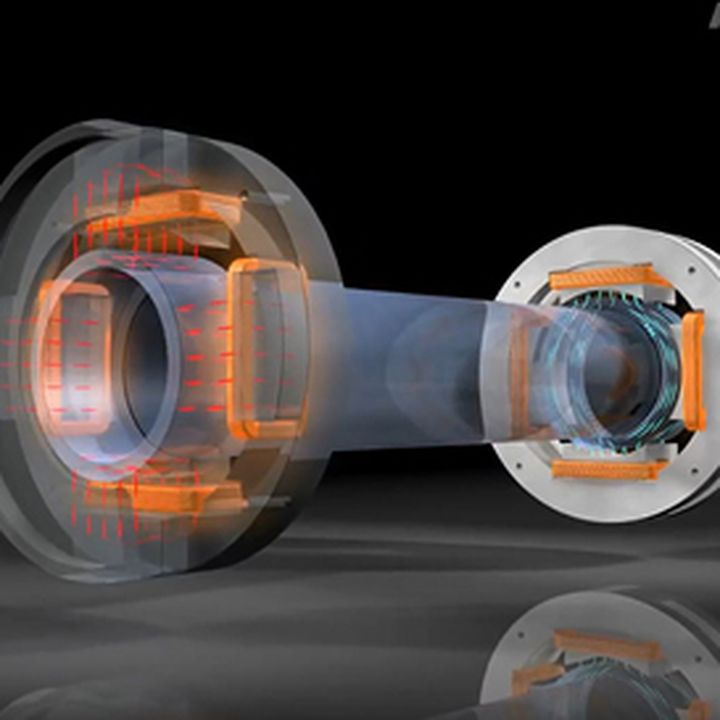

Maintenance-free magnetic bearings for the industrial sector

High-speed applications require high-quality bearing solutions.

Conventional bearing systems are subject to high wear and tear in the upper speed range, or their suitability for cycle-based operation is limited. Magnetic bearings with their contactless technology are non-wearing and maintenance-free. Also, they do not require any lubrication. Active magnetic bearings perfectly complement KEBA’s automated drive solutions and are used in many high-speed applications.

Your benefits at a glance

- Long-standing proven technology

- Industrial-scale robust technology

- Reproducible quality in series processes

- Broad range of process information for condition monitoring

- Energy supply from the drive DC link

Non-wearing

Outstanding availability without maintenance intervals

Efficient

Contactless operation without bearing friction

Flexible

Adaptable to process conditions

Oil-free

Clean processes without lubricants

Overview of our products

Based on our technology portfolio for magnetic bearing systems, we create tailor-made solutions for your specific requirements.

Actuators/sensors

Magnetic bearing components for optimal integration into market-specific drive solutions

- Compact 2-phase and 3-phase bearing technology

- Permanent-magnet-supported bearings for maximum energy efficiency and simple design

- Combined radial and axial bearings ensure short axial design length

- Patented high-resolution position sensors built into the magnetic bearings for maximum accuracy

- Built-in temperature sensors

Control electronics

Highly compact electronics for actuating and controlling the active magnetic bearings

- Control for 5 plus 1 axes

- Available as onboard electronics directly on the motor, or as a cabinet version

- Evaluation of high-resolution position sensors and integration of power electronics in one housing

- Magnetic bearing electronics based on standard servocontroller series

- Easy parameter configuration and control using software tools, bus systems and digital I/Os

- Easy integration into existing communication structures

- Available fully fitted with cables for connection to the magnetic bearing controller

Tools & functions

Easy commissioning and operation

- Commissioning and parameter configuration via a graphic user interface

- Group-based user access rights

- Adaptive unbalance compensation

- Adjustment of bearing damping and stiffness

- Provision of advanced process information via integrated sensor (e.g. vibrations, forces)

- Mains support operation for safe shutdowns in case of a power failure down to virtually zero speed

Our solution for your applications

Blower or turbine applications

Complete drive solutions for high-speed applications

- Optimal solution for blower, compressor, and turbine applications

- Complete drive train for high-speed applications

- Usable as motor or generator with magnetic bearing

- Completely maintenance-free

- Power: up to 300 kW

- Speeds up to 60,000 min-1 (depending on power, pressure ratio, and medium)

- Bearing forces: up 3500 N (axial)

- Impeller not included

- Attached magnetic bearing electronics for easy and low-cost installation

- Built-in water cooling system

Magnetic bearing machine tool spindles

Complete solutions for demanding processing tasks

- Magnetic bearing spindle solutions for processing tasks with specific requirements

- Power in the multi-kilowatt range

- Speeds up to 60,000 min-1

- Automatic tool clamping system

- Supports targeted periodic deflections of the shaft position in radial or axial direction

- Built-in minimum quantity lubrication (MQL)

Downloads

This might also interest you

LeviTurb

The most efficient and compact complete solution for magnetic bearing turbo blowers in aeration applications.

KeDrive D3

High-performance drive technology compactly combined. We offer you a fast, scalable and compact all-in-one system.

Thank you for your request. Our KEBA Customer Support will get in touch with you soon.

Locations

Business Areas

Newsroom

Edge

Chrome

Safari

Firefox