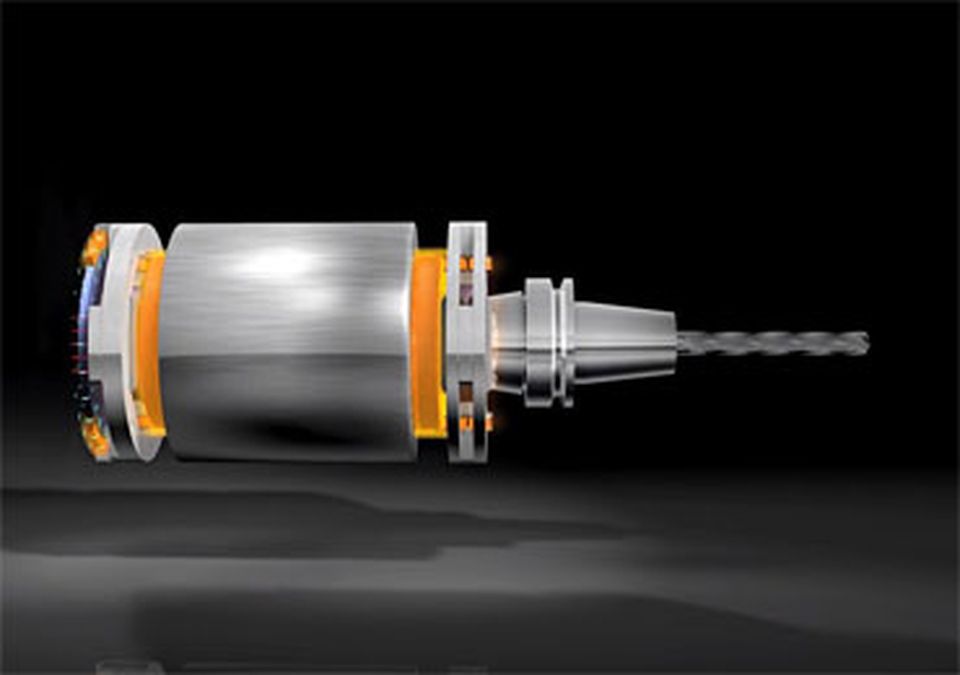

LeviSpin drill spindle

All benefits at a glance

Increased productivity

- Material removal rate increased by 200–400 %

- Reduced exit burr saves deburring in many applications

- Time-saving backward deburring through orbital motion

- Effective processing even of difficult-to-machine materials

Cost savings

- Tool wear reduced by 50 % and more

- Non-wearing magnetic bearings

- Greater sustainability thanks to minimal quantity lubrication or even dry machining in some cases

Improved quality

- Significantly improved surface quality of the workpieces thanks to efficient chip removal

- Workpiece-specific quality monitoring (controlled quality)

- Targeted shaft tilting for compensating mechanical machine errors

- Improved drill hole quality in deep-hole drilling through drill run-out compensation

Condition monitoring

- Built-in sensors ensure precise detection of process forces

- Detection of material layer thickness

- Layer recognition when using composite materials and automatic switching of process parameters

- Detection of tool wear (wear-based feedrate adjustment)

Improved quality

- Significantly improved surface quality of the workpieces thanks to efficient chip removal

- Workpiece-specific quality monitoring (controlled quality)

- Targeted shaft tilting for compensating mechanical machine errors

- Improved drill hole quality in deep-hole drilling through drill run-out compensation

Downloads

소재지

Please select your preferred language

Your browser is out of date

Internet Explorer is no longer supported. Please switch to a current browser to use keba.com to its fullest extent.

Edge

Chrome

Safari

Firefox

{{ location.street }}

{{ location.street2 }}

{{ location.zip }} {{ location.city }}, {{ countryName }}

AC Wallboxes:

{{ location.phone }}

DC fast charger:

{{ location.phone_dc }}

KEBA eMobility technical Support

KEBA eMobility technical Support

AC Wallboxes:

{{ location.emobility_support_phone }}

DC fast charger:

{{ location.phone_dc }}