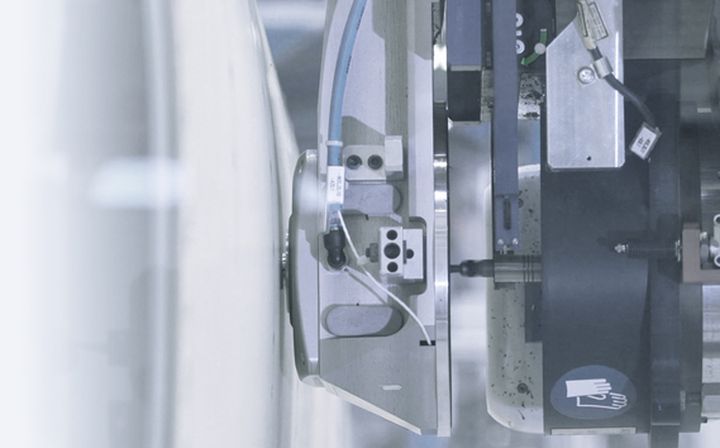

Magnetic-bearing spindles

Machining 4.0

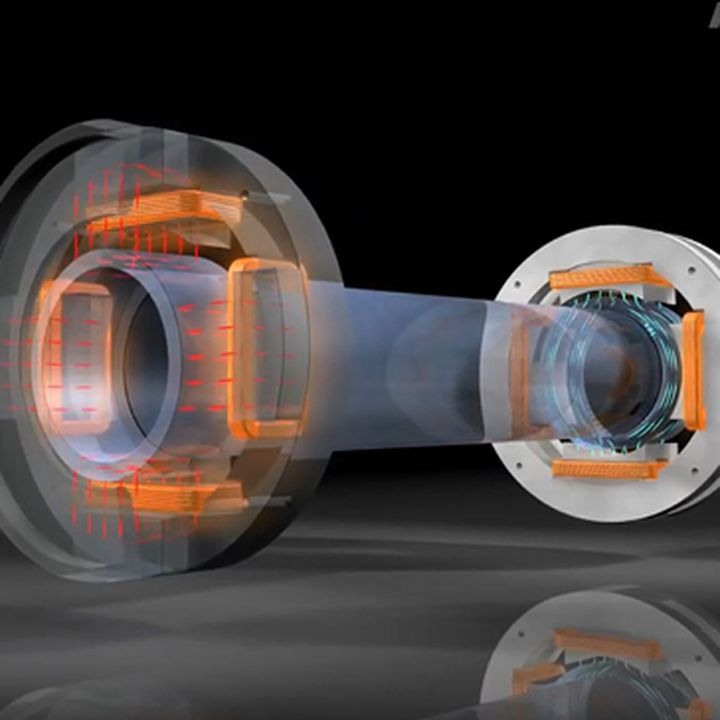

KEBA has been developing and selling magnetic-bearing systems for more than 20 years, and their continuous evolution has brought about the revolution of the machining sector. With their magnetic bearings, LeviSpin drill spindles can produce micro-movements on 5 planes. This makes it possible to oscillate the spindle shaft and thus generate a targeted chip break, to perform orbital movements, to move the shaft parallel, or to tilt the shaft. This produces numerous benefits.

6D technology in the drill spindle

The term 6D refers to the 5 degrees of freedom of the magnetic bearing in space plus the rotational movement of the shaft. The literature also uses terms like vibration-assisted machining, vibration-assisted drilling or vibration drilling, but these only offer some of the benefits listed below.

Increased productivity

Lower costs

Improved quality

Condition monitoring

Greater sustainability

Downloads

This might also interest you

Turbo Systems

Innovative drive and magnetic-bearing solutions by KEBA for a broad range of high-speed applications.

Servo controllers

The wide range of KEBA servomotor series offers you the optimal solution for your mechanical engineering needs.

Machine tool

KEBA has been active in the automation of machine tools for 40 years and has its proprietary CNC and robotics kernel.

Safety technology

KEBA provides modular safety solutions for innovative requirements in machine safety.

소재지

Edge

Chrome

Safari

Firefox