Complete solutions for the plastics industries

KePlast – because technology matters

Our Passion. Your Success.

Simplicity, modern operation, and strong performance are particularly important in controlling injection molding machines. With KEBA, you can rely on innovative automation solutions with the highest service quality. In line with its credo, Automation by innovation, we have been developing cutting-edge solutions optimized to your needs – because our passion is your success.

We speak the language of your industry

Thanks to years of experience in controlling injection molding machines, the experts from KEBA have acquired a comprehensive knowledge of the industry and technology. As a result, KEBA employees are able to respond to your requests in all areas quickly and competently and discuss issues with you on an equal footing in the specialist language that you are accustomed to.

Your benefits at a glance:

- Strong partnership: Reliable & instant support by a global acting team

- Premium quality & modern design: High-end brand design of hardware & software based on the latest technologies

- For all plastics machines & applications

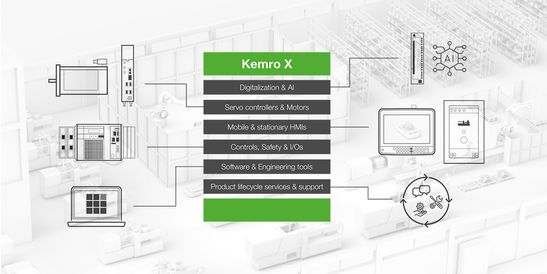

- Future-proof platform: Cutting-edge, modular, and scalable hardware & software platform

- Ready for Industry 4.0: Smart assistance systems for the highest productivity

The perfect solution for all processes

The control generation of KePlast provides the highest performance in combination with the shortest cycle time. The complete solutions stand out with the European brand quality and modern design both on hardware and software.

KePlast i1200: Product of the Year Nomination

We’re proud to announce that our newest KePlast i1200 system has been nominated for the “Product of the Year” awards in the Periphery category by the German plastics industry magazine PolyForm Next!

Super-fast and robust: Featuring a 125 µs reaction time, KePlast i1200 sets a new benchmark as KEBA’s fastest controller to date - the first powered by ARM technology and safeguarded by unique CPU protection features.

The voting is open until 31 January 2025!

The software makes the difference

Whether any kind of injection molding machine or other plastics processes machinery – all KePlast systems are based on a fully scalable and innovative software platform. The KePlast framework is extremely flexible.

The KePlast Software Framework offers perfect assistance in all phases of the automation cycle. Ready-to-use technology libraries for controlling temperature or pressure-based closed loops can be used instantly as well as various sets of software features and templates needed in any plastic machines.

Powerful software platform for your competitive advantage

The KePlast platform enables multiple communication protocol standards and interface specifications, such as OPC UA and EUROMAP. Due to its openness, any customer-specific individualization and the integration of 3rd party programs can be realized. The KePlast Application Framework with its integrated software libraries is a ready-to-use solution as well as a starting point for any requested modifications and extensions – in which the customers can bring in their own technology and application know-how.

KePlast Smart Functions

Faster & more accurate control technology with KEBA concepts

The latest achievements of our control engineering experts – the newest control engineering technologies and smart functions of KEBA & KePlast – in an informative, but interactive way.

Your benefits with KePlast

Stronger together

With our customers, we go for a partnership-based relationship that goes far beyond project support. In perfect symbiosis, we master ever shorter product lifecycles together. In an active dialog, we jointly design the best custom solutions together. The end of the series production is not the end of our partnership. It is the beginning of a new generation of machines.

Future-proof platform

KEBA technologies are based on a Linux platform with a strong community in the background. Due to its modularity and sophisticated software architecture, all KePlast controllers can be upgraded from a basic to a high-end system at any time, meeting the latest technology trends – supplemented by several functionalities and further smart assistance systems. This makes our KePlast control solutions future-proof.

Quick time-to-market

From initial consultation to system design, installation and series production support, the KEBA experts are available with their sound knowledge. Customized software adaptations to process control optimization can be done quickly and easily.

Available worldwide

A large team of highly educated application engineers is available worldwide. The locally-based teams put your plastics and injection molding machines into operation quickly and with skill.

Our customers trust in us

Digital solutions for the plastics industry

We speak the language of our industry and support our customers on their path towards digitalization with easy-to-integrate tools and solutions. Check out our video series about Digitalization @ KePlast.

Downloads

News & Events

The newest blog articles & events - here at a glance!

Thank you for your request. Our KEBA Customer Support will get in touch with you soon.