Technological depth meets trust: Future-proof die casting solutions

- References / Success Stories

- Plastics

- 8.5.2025

- Reading Time: {{readingTime}} min

Contents

Bühler Group is a technology concern headquartered in Switzerland that has been family-owned and operated for five generations. The company is a global leader in technologies and processes for food manufacturing and mobility solutions.

In order to optimally cover both of these focal points – food and mobility – on the market, Bühler’s business rests on two pillars: Grains & Food Solutions provides for safe and healthy foods and animal feed, for example in the processing of cereal grains for flour and animal feed, but also for the production of chocolate and pasta. The Advanced Materials Division supports the production of energy-efficient vehicles and buildings through solutions for glass coatings or the production of die-cast components.

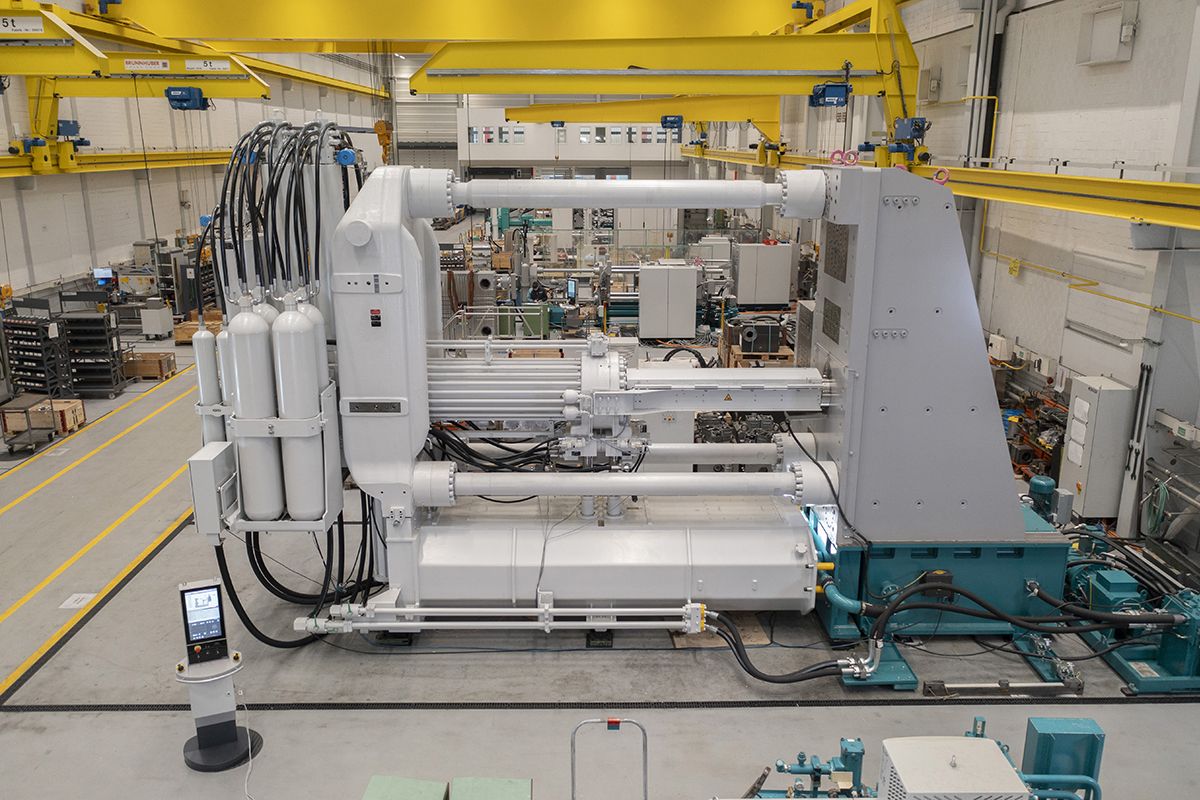

Bühler’s die casting division is a significant player in the market. The numbers tell a compelling story: Roughly 50% of all structural components for cars are manufactured using Bühler die-casting machines. In addition, about 25% of all die-cast products available worldwide are produced using Bühler technology. More than 1,000 foundries around the world rely on technology made by Bühler for their die-casting needs.

Challenge: extremely fast cycle times, open system architecture and text-based configuration

Bühler and KEBA have been working together for almost 30 years. When Bühler decided to stop the in-house development and production of IC controllers, they went through a selection process to find a suitable supplier for these items. Thanks to KEBA’s excellent reputation for quality on the market, Bühler selected KEBA.

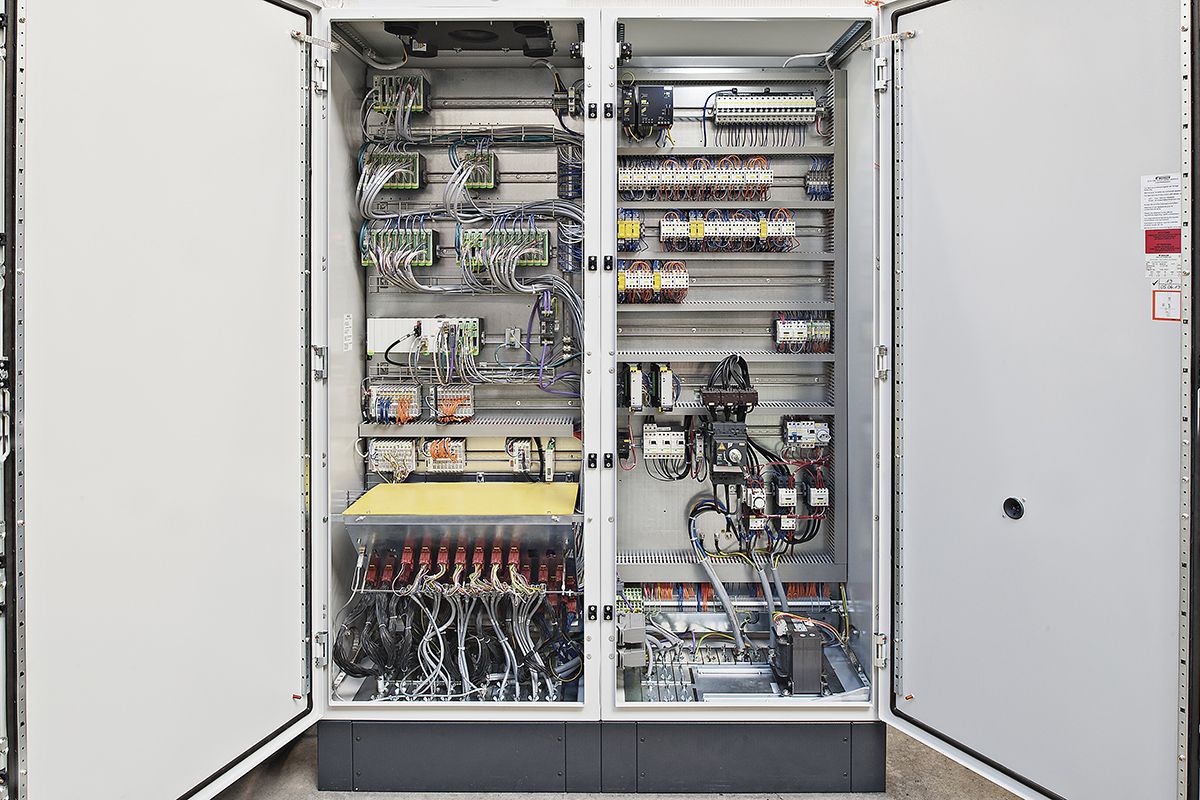

The challenge for KEBA was the speed and cycle times of the processes. One of the core processes consists in controlling the casting speed. This involves a three-stage electro-hydraulic control system in which the die-casting piston needs to accelerate from 0.5 m/s to more than 7-10 m/s within approx. 1 second, and then decelerate again to 0.5 m/s. On the one hand, this requires highly precise measuring cards; on the other hand, it also requires very fast read and write cycles in order to ensure disturbance rejection. Disturbance rejection enables a system to maintain stability and accuracy even if internal or external disturbances act on the system. It is thus a core element for the robustness and adaptability of industrial control systems. Lukas Labhart, Automation Team Manager at Bühler Group, says: “At that time, KEBA was the only manufacturer capable of realizing the kind of fast cycle times demanded by a highly complex control system. We are talking response times of 200 microseconds.” The competitors in those days needed a lot longer.

At that time, KEBA was the only manufacturer capable of realizing the kind of fast cycle times demanded by a highly complex control system. We are talking response times of 200 microseconds.

"KEBA’s open system architecture and our goal to only offer systems that supported automated configuration were a perfect match."

Open system architecture meets flexible configuration

The first system that Bühler ordered was of the K1 generation. Today, Bühler is using controllers from the KeControl C5 series. Labhart explains: “That means that we have already used four generations of this control system – which also means that we have been happy with KEBA solutions for a pretty long time.”

In addition to fast response times, the system also stood out for its great system performance. The overall system allowed Bühler to configure hardware and software with much greater efficiency. Says Labhart: “Even then, KEBA was pursuing a unique approach: KEBA’s open system architecture and our goal to only offer systems that supported automated configuration were a perfect match.”

All of Bühler’s die-casting machines are series products which can, however, be customized to suit particular customer needs. This only works if there is a flexible system for the easy configuration of hardware and software. Text-based configuration was a must-have for Bühler. “This advantage is still paying off today. The databases and mechanisms created back then are still defining and simplifying order processing and make the system highly efficient. We have maximum flexibility and keep our development costs low”, says Labhart. Software can be created and customized with the push of a button without any need for developers to touch the code. Options are easy to activate or deactivate.

Trust through continuity: partnership at eye level

Bühler describes the cooperation with KEBA as a “true partnership”.

Says Labhart: “Our problems are also your problems, and we tackle them together. The KEBA team takes our suggested improvements and our requests seriously and integrates them into the planning of future products.”

In this context, Bühler also points to the size of KEBA as a company. There are some suppliers of automation solutions that are much bigger. But that is not necessarily always an advantage. “KEBA’s size feels comfortable and manageable, and in combination with their flat hierarchies, it means that we have quick and easy access to the technology experts, which is an enormous boon for us.”

Quick response times and the speedy development and provision of solution approaches are the result. “In addition,** our contacts at the company remain the same**. That creates trust, and as a result, there is great familiarity and a thorough understanding of our needs and our processes,” says Labhart.

How to describe KEBA’s style in just three words? “Open, respectful, customer focused”, says Labhart.

"KEBA has an excellent reputation for quality. We were also impressed by the willingness to work with us to develop – and to continue to shape to this day – a solution that meets the needs of Bühler exactly."

Looking ahead: cyber-security and over-the-air capability

Today's hot topic in the world of automation, aside from the marketability of over-the-air solutions, is the issue of cybersecurity. “In cooperation with KEBA, we must and will overcome these challenges and will be ready when the new Machinery Directive becomes law,” says Labhart.