Kemro X - Industrial Automation Platform

The platform for industrial automation

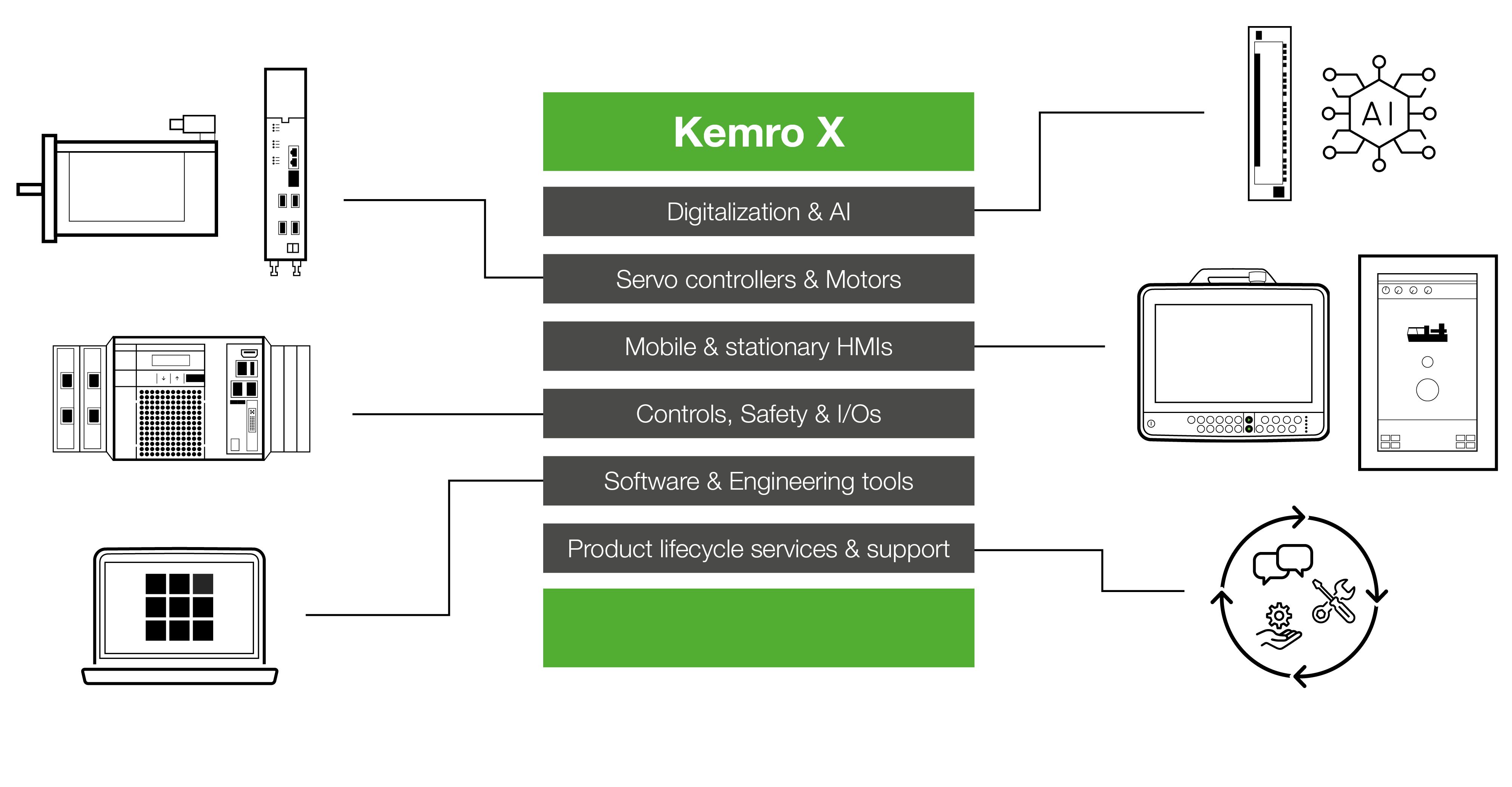

Kemro X is an easy-to-use, open, and modular platform designed for advanced industrial automation solutions.

Our modular portfolio allows users to combine components such as apps, HMIs, controllers, or technology packages according to their requirements.

This flexibility helps us provide solutions tailored to individual customer needs while offering cross-industry applications.

Thanks to standardized interfaces and an open system architecture, Kemro X allows the installation of third-party software, enabling customers to integrate their own applications or services. This promotes the reusability of existing software and allows flexible expansion of control functionality.

Unlike traditional PLC systems, Kemro X offers an open environment that is not limited to manufacturer-specific function blocks.

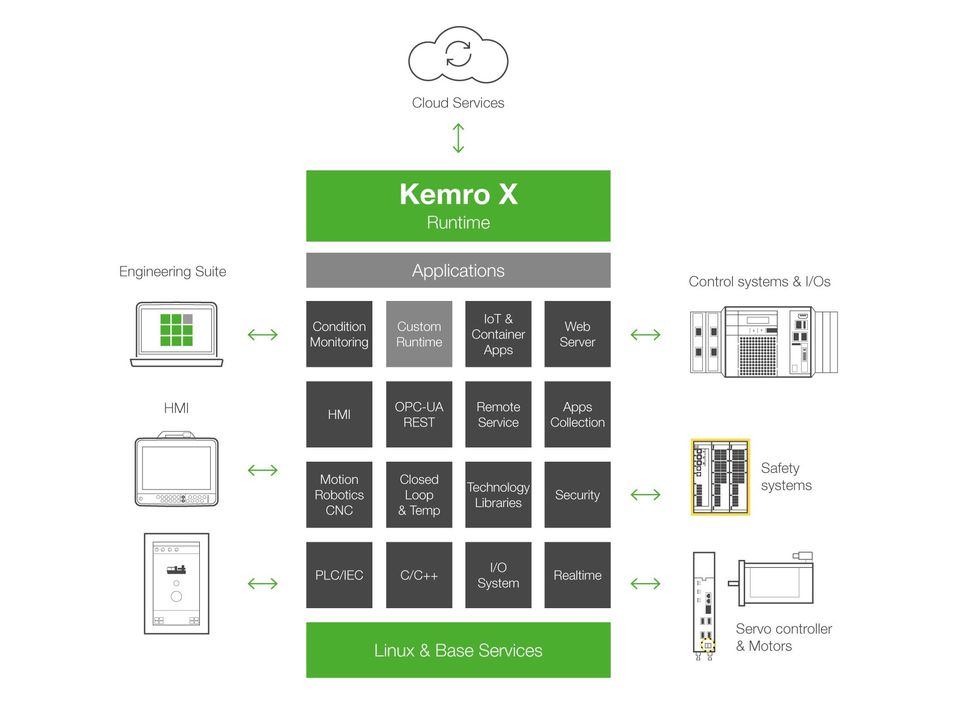

Kemro X Runtime

Control system with open software architecture

Kemro X Runtime is based on a flexible, Debian-based Linux system and offers modular expansion stages - from real-time operating systems with standard APIs to industry solutions for robotics, injection moulding technology, CNC and visualization.

Thanks to its open architecture and standardized interfaces, the system can be individually expanded. In-house software modules and 3rd party applications can be easily integrated. Middleware enables fast, efficient data exchange.

The benefits of Kemro X at a glance

Open system architecture

The core of the Kemro X platform is a Debian-based Linux operating system. Linux is open-source and is easy to run, analyse, share and modify. In contrast to closed systems, existing suppliers and competences can be retained.

Flexible und scalable

For decades, we have acquired in-depth industry knowledge and designed industry-specific solutions that can be reused and expanded. As a result, more and more modules are being created on the Kemro X platform that are tried and tested, adaptable and quickly ready for use.

3rd party integration

Thanks to the standardised EtherCAT, Ethernet IP and Profinet interfaces, customer-specific hardware and software components and software from third-party providers can be integrated more easily into Kemro X. This enables a high degree of customisation for customers.

Safe & reliable

We focus on holistic security solutions and do not consider OT and IT security separately. Ensuring data security, protecting innovations and confidential information are our top priorities.

Fast time-to-market

From the initial consultation to system design, installation and series support, the KEBA experts are always available with their in-depth knowledge. Fast response times to customer-specific adaptations or optimisations are a matter of course at KEBA.

Global service & support

From the long-term and reliable availability of spare parts, on-site service and remote support to comprehensive technical documents and downloads, KEBA responds flexible and quickly to individual support and service requests.

Frequently Asked Questions

Do you have questions about our automation platform? We have compiled answers to the most frequently asked questions for you here.

Kemro X stands for openness in hardware and software. Drives, HMI devices,... can also be operated on 3rd party controllers via various standard interfaces (EtherCAT, Profinet,...). The Kemro X Runtime Environment software is based on a Debian-based Linux. This is open source and a modular operating system which is being further developed by software developers all over the world.

Applications can be easily installed and uninstalled by the user. This can be done either ‘offline’ via USB stick (if desired, fully automatically when plugged in) or online via a software server (on-premise or in the cloud). The standard Debian repository mechanism is used in the background.

Kemro X offers the greatest advantages in series machine construction or in plant construction with a high degree of reutilisation. Kemro X is less suitable for the process industry. The focus is on applications where fast, dynamic, precise movements are required - i.e. where servomotors are used.

We distinguish technically between ‘master’ and ‘slave’. Our focus is on EtherCAT (as a master or slave), as it is widely used in series machine construction. We support the ‘slaves’ (called differently depending on the fieldbus - ‘adapter’ for EtherNet IP, ‘device’ for Profinet) for connections to higher-level systems or for individual product sales within a machine.

This depends heavily on the required application. Kemro X is designed for series machine construction, i.e. the product portfolio for equipping a typical machine is available from KEBA. If a product is missing, it can be integrated relatively easily due to the openness (e.g. a special device that is integrated via EtherCAT).

Kemro X controllers use Linux/Debian as the operating system. You can choose between Windows and Linux for our HMI devices. Linux is widely used (IoT, server, cloud), scalable, reliable, runs very stably (even on older hardware) and is rarely the target of malware attacks compared to other operating systems. Debian is a well-known Linux distribution. Windows is often used for visualisation devices. The main purpose is when existing Windows-based tools are already available and reused.

Kemro X enables real C/C++ programming (it is not transformed in the background to another language, e.g. IEC code). External C libraries can be used and programming with any IDE is possible (KEBA offers an IDE as an out of the box solution). C/C++ is platform-independent and therefore very portable. IEC61131-3 programming based on CODESYS is also possible. Scripting languages such as LUA or Python can be used in a non-real-time context.

In addition to numerous Kemro X apps, 3rd party applications can also be installed. The software architecture is designed to be largely hardware-independent. In combination with KEBA controllers, there is added value in the area of service, hardware EtherCAT with reduced jitter and fast control, utilisation of real-time clock, retain data (SRAM,...)

Blog: How open should an automation solution be?

For the successful implementation of a modern automation system, the mere integration of hardware into a higher-level system is no longer sufficient. What is needed is a shared and software-based "ecosystem" that must be flexible, transparent, scalable and, above all, open.

This might also interest you

Servo controllers

Flexible, compact and easy-to-operate drive controllers that maximise the dynamics and precision of your machine

HMI

Our KeTops offer customisable, high-performance hardware and software for mobile and stationary operating devices for ideal visualisation.

Industrial software

Turnkey and customized industry solutions in an open, powerful & scalable control system for every phase of automation.

Solutions for digitalization

With our ‘open platform’ architecture, we enable the design freedom needed to realise Industry 4.0 solutions.

Thank you for your request. Our KEBA Customer Support will get in touch with you soon.

Locations

Newsroom

Edge

Chrome

Safari

Firefox