Predictive Maintenance

for Fleets

Intelligent Maintenance, Maximum Vehicle Availability

powered by AI

KEBA Digital uses Artificial Intelligence to detect maintenance needs in truck fleets early. This keeps vehicles on the road longer, reduces costs, and makes planning more reliable. By predicting issues before they occur, we turn downtime into uptime and keep your logistics moving efficiently.

The Challenge:

Unexpected Breakdowns and Costly Downtime

In transport logistics, unplanned vehicle failures are a major cost driver: downtime causes delivery delays, customer dissatisfaction, and high replacement costs. At the same time, rigid maintenance intervals lead to unnecessary and inefficient resource usage.

What’s missing is a predictive maintenance strategy that analyzes and forecasts actual vehicle conditions – instead of following static schedules based on mileage or time.

The Solution:

Predictive Maintenance with AI

KEBA Digital develops AI models that analyze sensor, telematics, and operational data in real time. This enables early detection of potential defects or wear – before they cause breakdowns.

Our solution empowers data-driven maintenance decisions, optimizes workshop capacity, and extends vehicle lifespan.

Real-Time Condition Monitoring – Stay Safe on the Road

AI continuously monitors engine, tire, brake, and temperature data. Patterns indicating potential issues are automatically detected.

Benefits:

- Early detection of wear or malfunctions

- Reduced downtime through planned maintenance

- Lower maintenance costs through targeted interventions

Maintenance Demand Prediction – Data-Driven and Precise

AI calculates probabilities for component failures based on usage intensity, load, environmental factors, and historical error data. This allows forecasting the ideal maintenance time to minimize costs and downtime.

Beneftis:

- Accurate planning of service intervals

- Optimal utilization of workshops and technicians

- Extended fleet lifespan

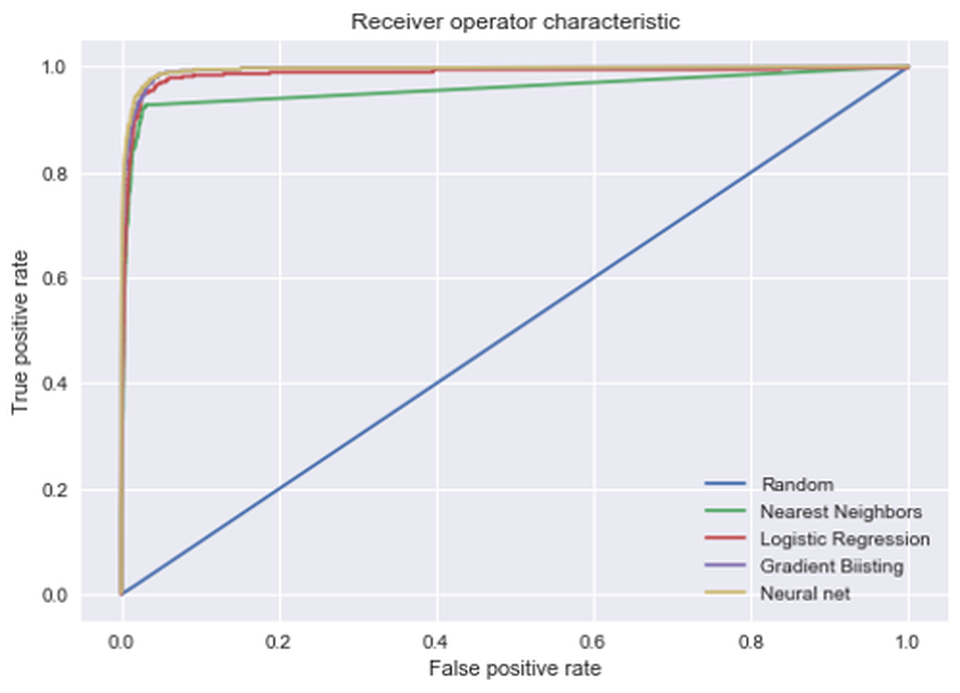

Model Comparison for Failure Prediction: ROC-AUC Curve

The ROC-AUC curve shows how reliably different models can predict truck failures. It is a key tool for evaluating the quality of predictive maintenance algorithms and finding the optimal balance between early maintenance and unnecessary interventions..

Why it matters:

Model performance comparison: Identifies the most accurate prediction method

Optimal thresholds: Helps balance sensitivity and specificity

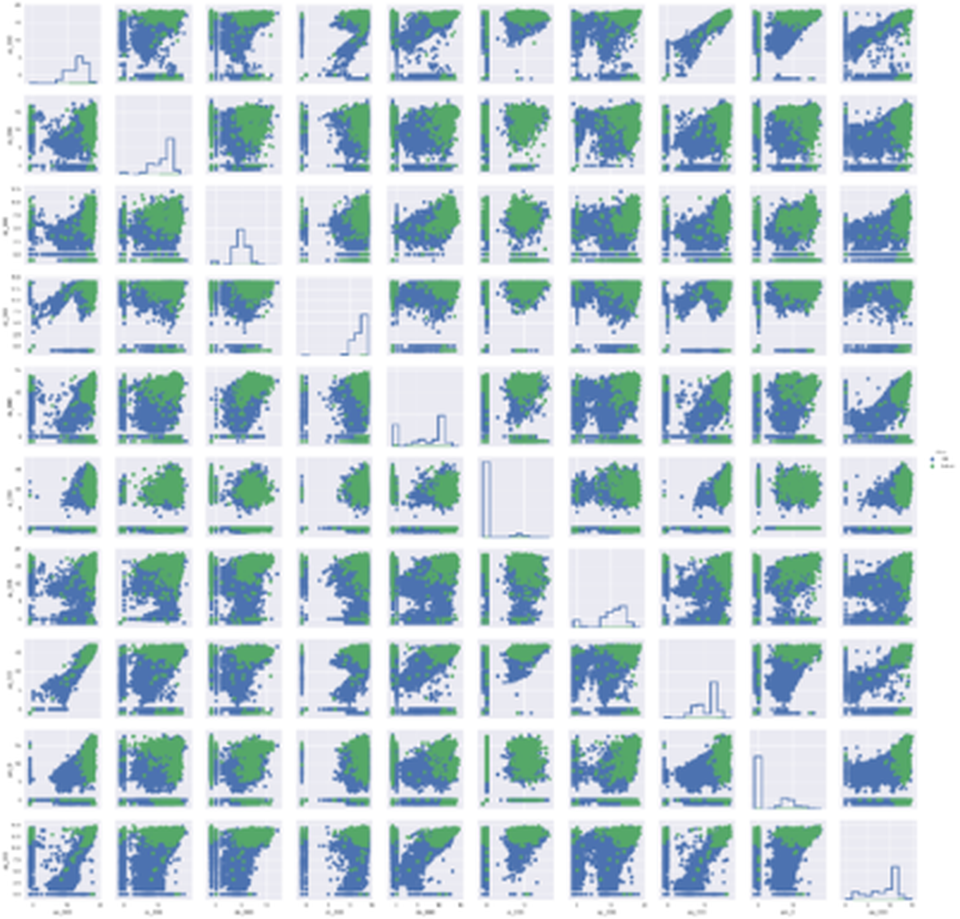

Understanding Sensor Data: The Foundation for Predictive Maintenance

The scatterplot matrix illustrates relationships between numerous air pressure system measurements in truck fleets. Such analyses reveal patterns and correlations critical for failure prediction. Visualizing complex data uncovers connections that indicate potential critical states – creating a solid basis for data-driven maintenance strategies.

Why it matters:

Detect critical correlations: Shows which parameters strongly interact

Highlight anomalies: Outliers may indicate upcoming failures

Feature selection for AI models: Basis for precise failure predictions

More transparency: Complex sensor data becomes understandable and actionable

Technological Foundation

KEBA Digital combines data integration, AI models, and edge computing into a scalable solution for fleets of any size.

- Machine Learning (Random Forest, XGBoost)

- Deep Learning (von LSTM bis hin zu KAN und NBEATS)

- Anomaly Detection

- Edge Computing

- Predictive Analytics

Your Benefits

with KEBA Digital

Cost Reduction

Maintenance based on actual needs instead of fixed intervals

Efficiency Boost

Early defect detection prevents downtime

Sustainability

Less wear, lower energy consumption

Productivity Boost

Higher vehicle availability and predictable operations

Thank you for your request. Our KEBA Customer Support will get in touch with you soon.

Locations

Newsroom

Edge

Chrome

Safari

Firefox