AI-Powered Forecasting & Planning in Manufacturing

More Transparency, Fewer Bottlenecks

With KEBA Digital’s solutions for forecasting and planning, you anticipate demand early, optimize production and supply chains, and maximize resource efficiency. By transforming uncertainty into actionable foresight, you create a foundation for resilient operations and profitable growth.

The Challenge:

Lack of Planning Certainty and Inefficient Processes

Many industrial companies struggle with inaccurate forecasts and limited controllability: production capacities are underutilized, material shortages occur unexpectedly, and supply chains are vulnerable to external disruptions.

Fluctuating demand, volatile lead times, and missing synchronization between procurement, production, and logistics increase the risk of bottlenecks and cost explosions. The result: overproduction, stockouts, and unnecessary buffer inventories.

The Solution:

AI-Driven Forecasting & Planning Models

KEBA Digital leverages Artificial Intelligence to link sales, order, and production data with seasonal patterns, market trends, and external factors.

This enables precise forecasts for demand, capacity utilization, and lead times. By integrating these insights into dynamic planning models, businesses gain real-time adaptability and resilience against volatility.

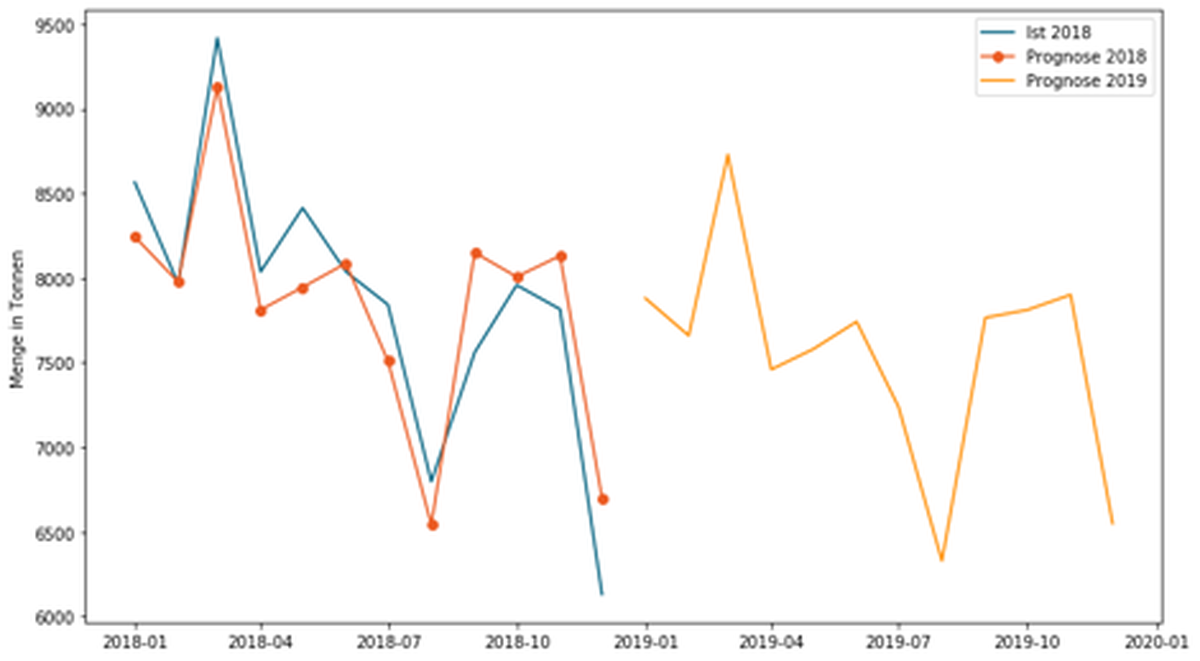

Demand Forecasting – Predict Needs Accurately

Our AI analyzes historical sales, order, and production data and combines them with seasonal patterns and market trends. This allows accurate demand predictions at product, customer, or segment level, optimizing production and inventory planning.

Benefits:

- Improved production and inventory planning

- Avoidance of stockouts and overproduction

- Higher delivery capability

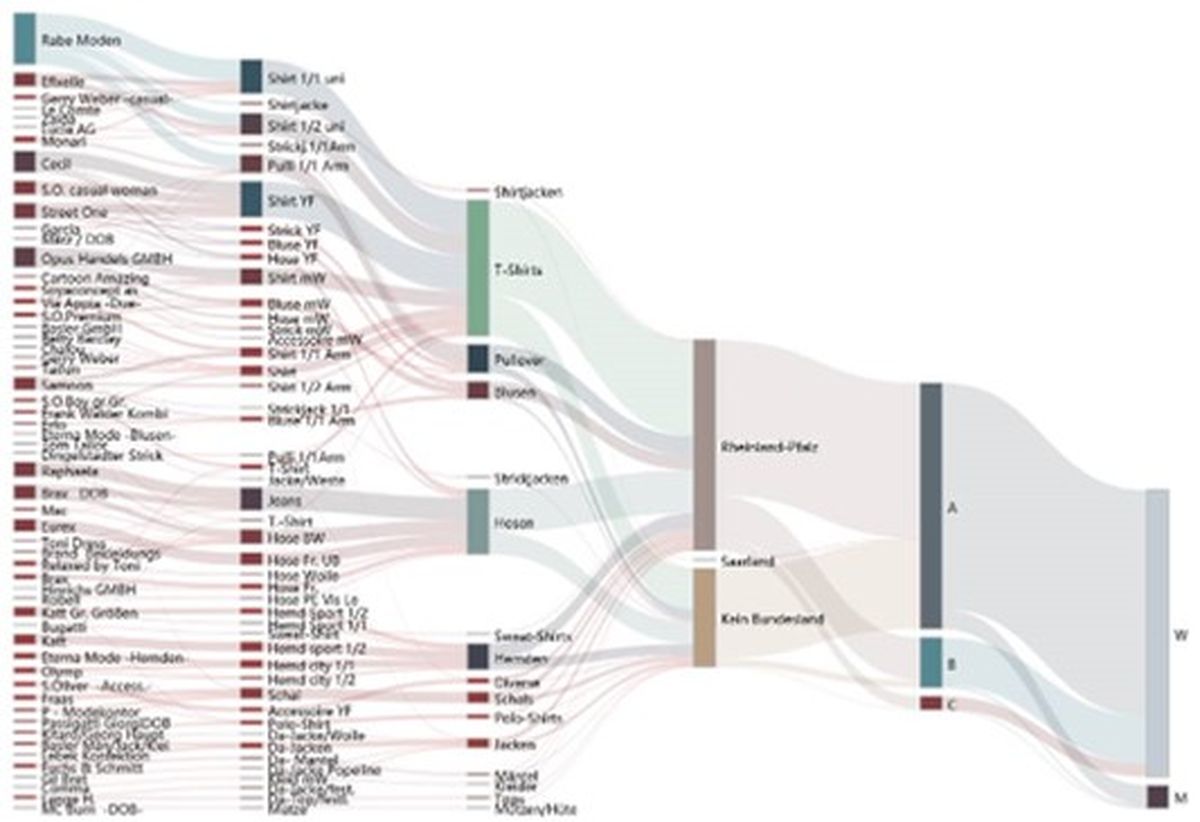

Supply Chain Forecasting & Optimization – Detect Risks Early

AI evaluates production, inventory, transport, and supplier data across the entire value chain. It predicts lead times and identifies potential bottlenecks early. Enhanced by graph-based network analyses and simulation models, material flows can be optimized and safety stocks reduced.

Benefits:

- Early risk detection in supply chain disruptions

- Optimized material flows

- Reduced safety inventories

Capacity Forecasts & Production Planning – Use Resources Efficiently

Fluctuating order volumes and seasonal effects often lead to inefficient utilization. AI-powered forecasts detect workload peaks early and enable proactive planning of production resources.

Benefits:

- More efficient capacity planning

- Avoidance of bottlenecks

- Reduction of idle times

Technological Foundation

KEBA Digital combines cutting-edge machine learning methods, statistical models, and data science approaches into an integrated solution for intelligent planning.

- Time series models

- Graph Analyses

- Deep Learning

- Simulation models

Your Benefits

with KEBA Digital

Cost Reduction

Less overproduction and fewer stockouts lower inventory and material costs

Efficiency Gains

Automated forecasts optimize production and resource utilization

Planning Reliability

Early risk detection stabilizes supply chains and reduces uncertainty

Competitive Advantage

Better availability increases customer satisfaction and revenue potential

Thank you for your request. Our KEBA Customer Support will get in touch with you soon.

Locations

Newsroom

Edge

Chrome

Safari

Firefox