Production & Process Optimization for Manufacturing with AI

Less Waste, More Efficiency

With our solutions for production and process optimization, you detect errors early, control machines dynamically, and ensure stable operations. This drives higher quality and lower costs while unlocking new levels of efficiency and sustainability. By turning data into actionable insights, we help manufacturers move from reactive problem-solving to proactive performance management.

The Challenge:

Errors, Energy Losses, and Unstable Processes

Many companies face inefficient production workflows: quality deviations are detected too late, machines do not run energy-efficiently, and process disruptions often go unnoticed.

The result: scrap, rework, high operating costs, and safety risks. Ultimately, rising costs, wasted resources, and untapped data potential.

The Solution:

AI-powered Production & Process Optimization

KEBA Digital uses Artificial Intelligence to continuously analyze production data, sensor readings, and control parameters.

This enables automatic error detection, energy optimization, and early identification of process anomalies.

Quality Control & Error Detection – Prevent Waste

Our AI automatically detects quality deviations and production errors before they lead to high costs. Image processing and deep learning models analyze products in real time to ensure stable processes.

Benefits:

- Reduction of scrap and rework

- Early error detection for consistent quality

- Fewer complaints and higher customer satisfaction

Machine Control & Energy Optimization – Efficiency Through Optimal Control

AI-driven control dynamically adjusts production parameters to reduce energy consumption and operating costs. Reinforcement Learning and model-based methods ensure optimal settings while maintaining quality.

Benefits:

- Lower energy consumption and reduced operating costs

- Sustainable production without compromising quality

- Automated adaptation to changing conditions

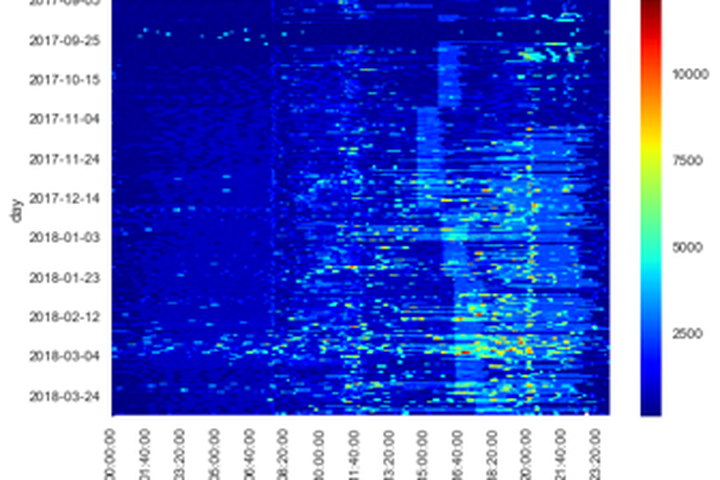

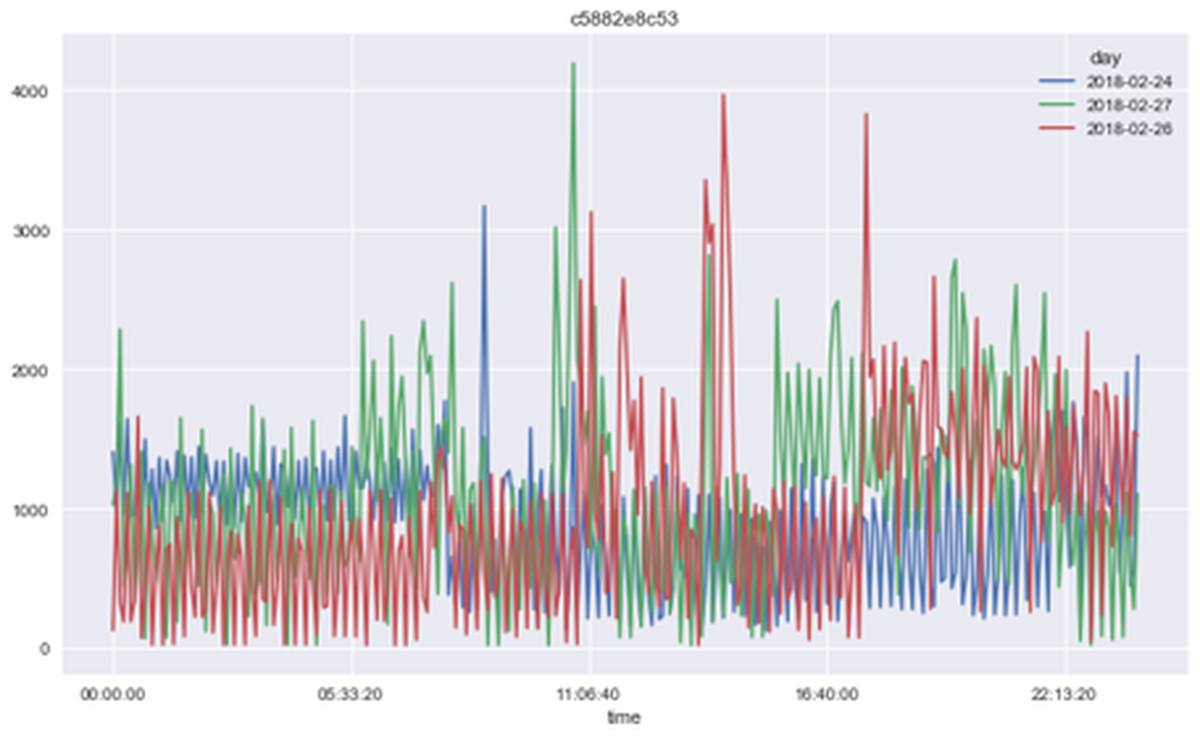

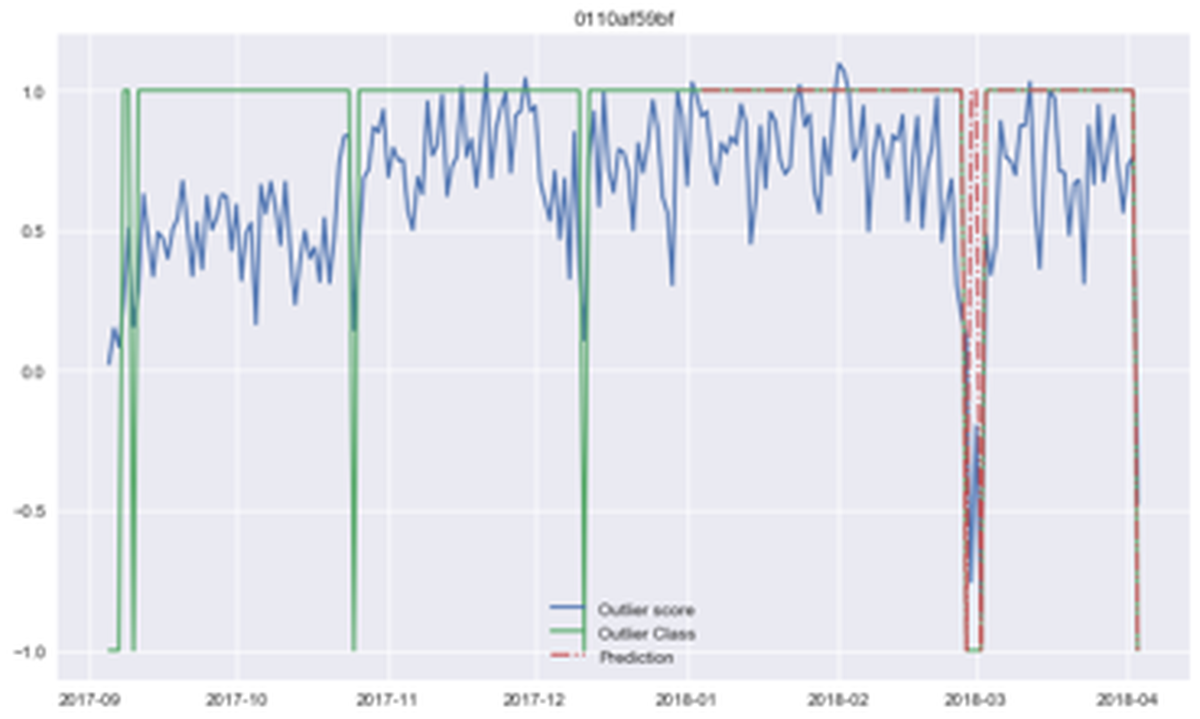

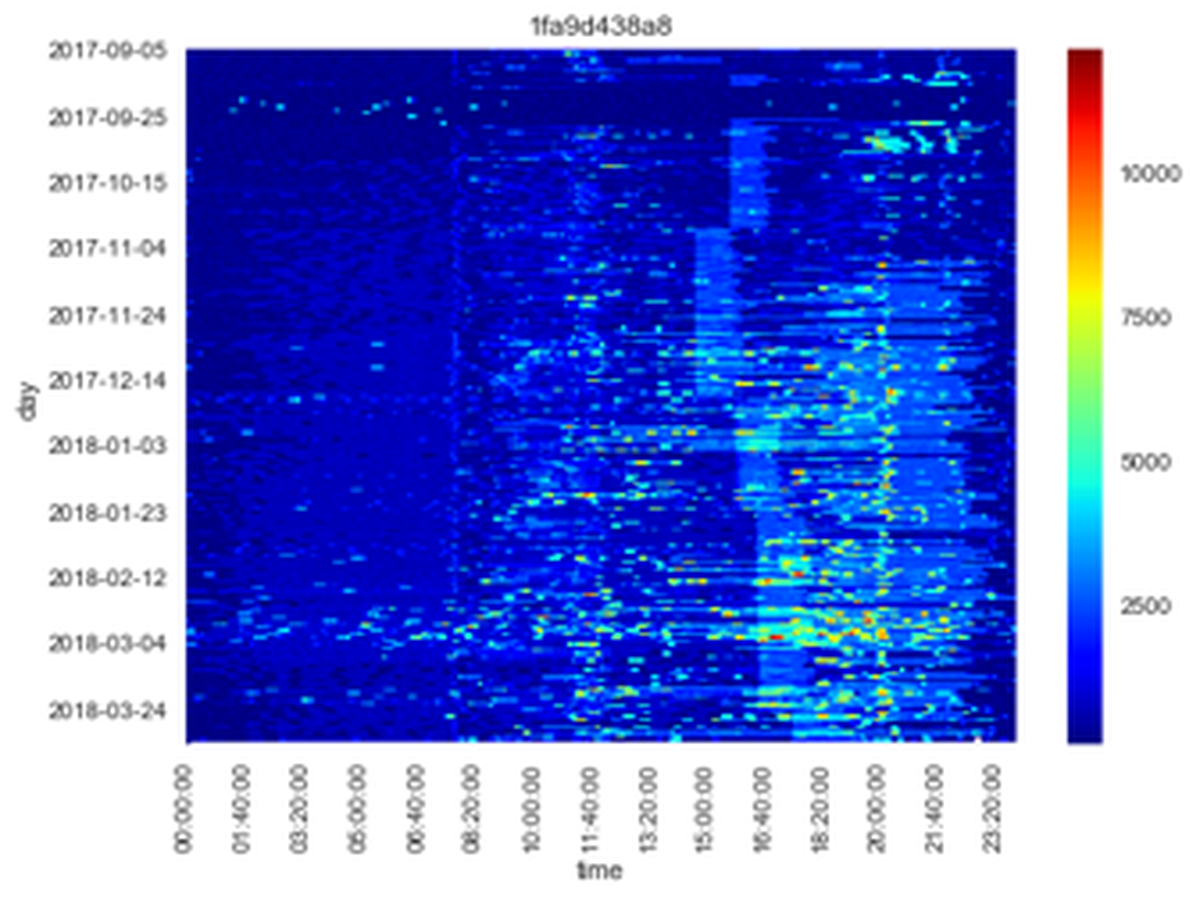

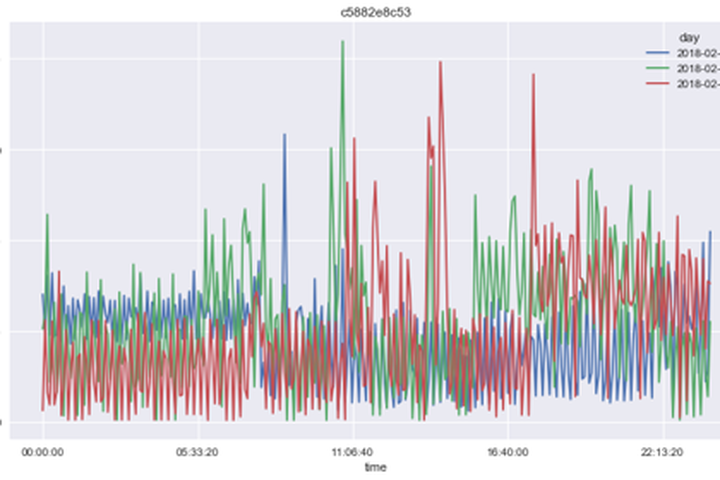

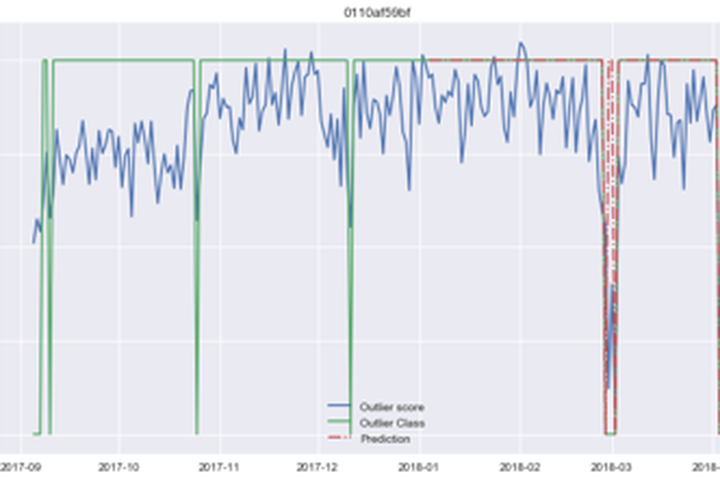

Anomaly Detection – Identify Disruptions Early

Production and sensor data are continuously analyzed by our AI to immediately identify unusual process patterns or abnormal machine behavior. This minimizes risks and prevents downtime.

Benefits:

- Early warning for disruptions or quality issues

- Prevention of unplanned downtimes

- Greater process security and stability

Visualizations of AI Use Cases for

Production & Process Optimization

Technological Foundation

KEBA Digital leverages cutting-edge AI, combined with Data Science and IoT integration, to intelligently control and continuously optimize production processes. The key building blocks include:

- Computer Vision & CNNs

- Time-Series Analyses

- Anomaly Detection

- Reinforcement Learning

- Optimal Control

- IoT-Data Integration

Your Benefits

with KEBA Digital

Cost Reduction

Minimize scrap and cut energy consumption to lower production costs.

Efficiency Boost

Automated control and real-time analytics streamline operations.

Quality Assurance

Early defect detection reduces rework and customer complaints.it

Process Stability

Anomaly detection prevents downtime and ensures continuous production.

Thank you for your request. Our KEBA Customer Support will get in touch with you soon.

Locations

Newsroom

Edge

Chrome

Safari

Firefox