Predictive Maintenance

for Manufacturing

Fewer failures, greater efficiency

With the predictive maintenance solutions from KEBA Digital, you can detect failures before they occur. Sensor and IoT data is intelligently analyzed to optimally schedule maintenance activities, reduce costs, and maximize equipment availability.

The Challenge:

Unplanned downtime and rigid maintenance cycles

Many industrial companies lose time and money due to inefficient maintenance: servicing is often carried out at fixed intervals without taking actual wear and tear into account. The result is unplanned machine downtime that causes high costs, production losses, and delivery delays.

In addition, spare parts are often unavailable because demand is not forecast in time. The outcome: rising maintenance costs, increased production risks, and untapped potential in existing data.

The Solution:

AI-Powered Predictive Maintenance by KEBA Digital

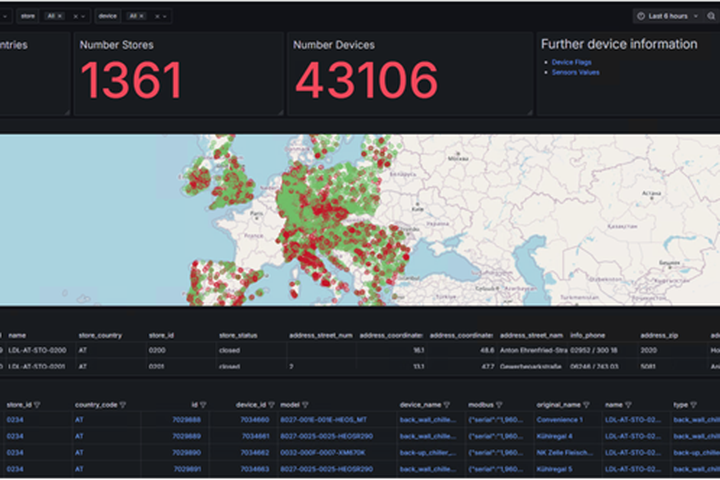

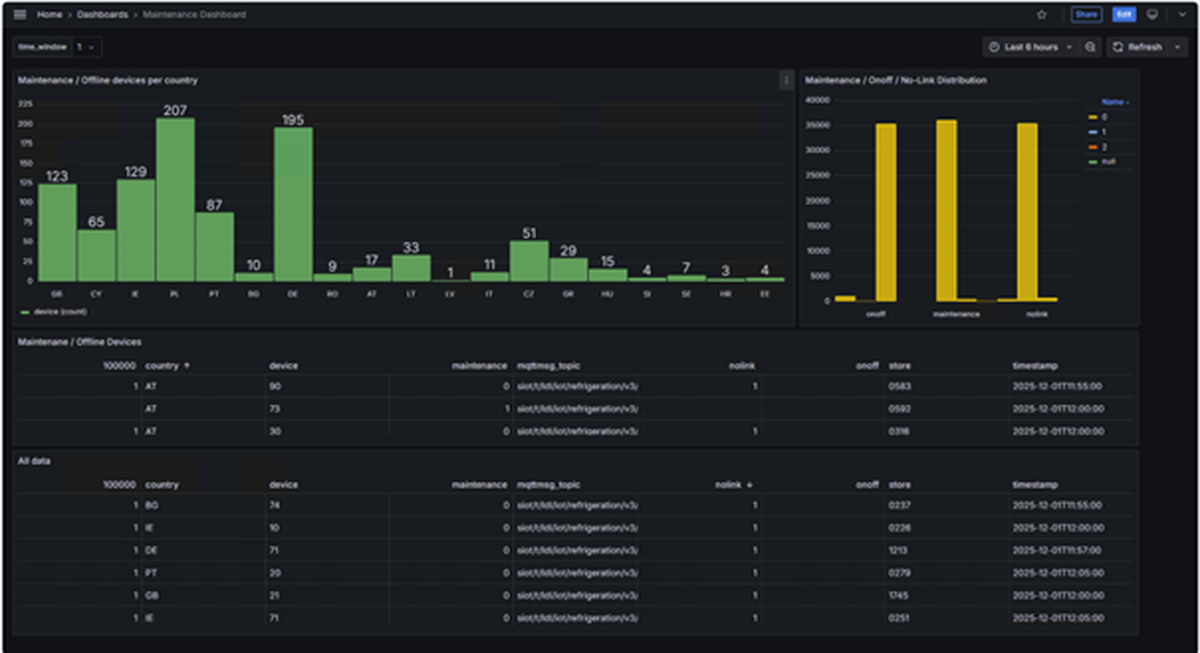

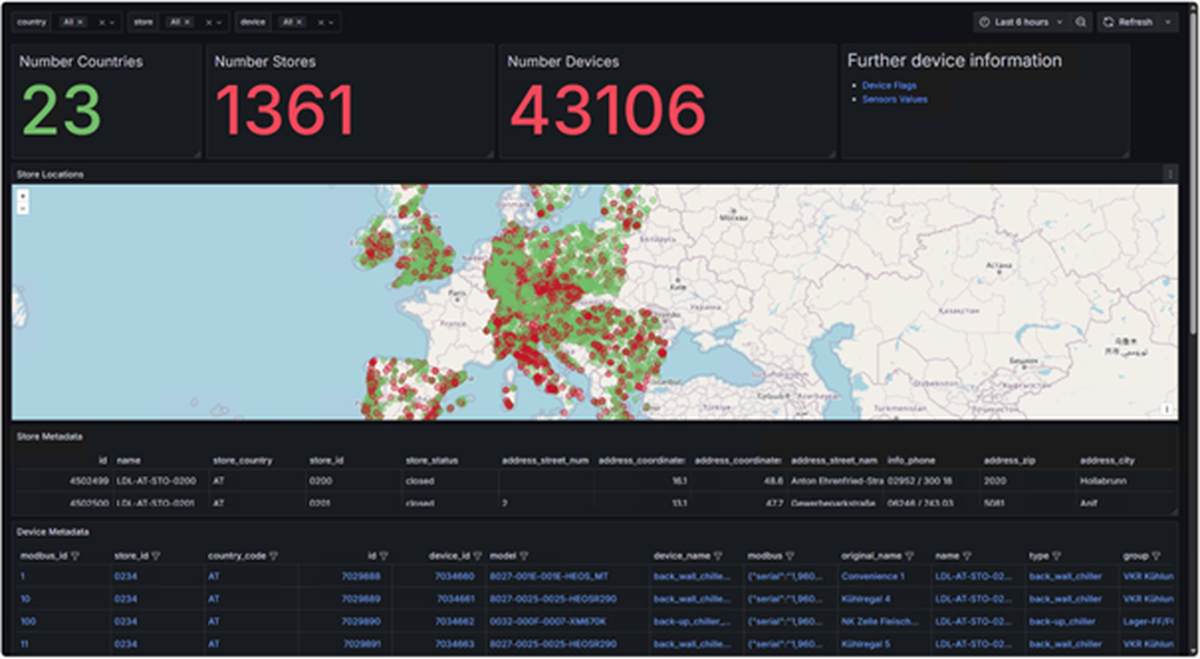

KEBA Digital leverages state-of-the-art AI technologies to continuously and intelligently analyze sensor data, operating parameters, and historical maintenance information. By combining machine learning, IoT analytics, and data-driven forecasting models, we create a system that goes far beyond traditional maintenance approaches.

The goal: detect anomalies early, accurately predict failures, and plan maintenance activities based on actual needs. For maximum equipment availability, lower costs, and significantly higher efficiency across the entire maintenance value chain.

Condition Monitoring & Anomaly Detection – Identifying Issues Before They Arise

Our AI continuously analyzes sensor data such as temperature, vibration, pressure, and power consumption to identify even the smallest deviations in machine behavior at an early stage. This makes it possible to detect potential damage before it leads to costly failures.

Benefits:

- Reduction of unplanned downtime

- Extended machine lifespan

- Higher process stability

Maintenance Timing Optimization – Efficiency Instead of Rigid Intervals

Predictive maintenance models forecast the optimal time for maintenance based on actual wear and operating conditions. This avoids unnecessary maintenance activities and enables targeted use of resources without compromising operational safety.

Benefits:

- Cost-efficient maintenance through demand-driven planning

- Minimization of production interruptions

- Improved resource utilization

Spare Parts & Resource Planning – Proactive Instead of Reactive

AI-driven forecasts for spare parts demand and service routes enable optimized logistics and planning. This ensures that the right parts and technicians are available at the right time, significantly improving service quality and delivery reliability.

Benefits:

- Avoidance of delivery delays and production stoppages

- Reduction of inventory costs through demand-based stocking

- Higher efficiency across the entire maintenance chain

Technological Foundation

KEBA Digital combines machine learning, IoT analytics, and data science into a powerful maintenance framework:

- Time series models

- Anomaly detection

- Deep learning

- Simulation models

Your Benefits

with KEBA Digital

Cost Reduction

Lower inventory and staffing costs through data-driven planning

Efficiency Gains

Automated forecasting and decision support

Sustainability

Less waste and transportation through more precise planning

Increased Revenue

Better product availability and higher customer satisfaction

Thank you for your request. Our KEBA Customer Support will get in touch with you soon.

Locations

Newsroom

Edge

Chrome

Safari

Firefox