Solutions for mechanical engineering

Products and solutions for your success

Highest performance and cost efficiency

Mechanical engineers must think bigger in order to differentiate themselves. This requires groundbreaking technologies, future-proof solutions and trusting partnerships. KEBA offers future-oriented industry 4.0 technologies for mechanical engineering and robot production, which enable worldwide networking with cloud-based data management and intelligent IT integration. Both hardware and software are optimized for machine automation, injection molding machines and robotics. They offer numerous communication standards such as Ethernet with OPC UA, fast and secure data storage for predictive analytics and maintenance, and other customer-specific adaptations.

Your benefits at a glance

- suitable operating solution for every application

- unique selection of mobile and stationary HMIs

- open and scalable automation system

- agile partnership, future-proof overall system

Individual, optimized automation solutions

Well-founded know-how in application is the key to success for mechanical engineers and industrial companies. Therefore, the focus is clearly on its further development; only very limited resources are available for basic automation.

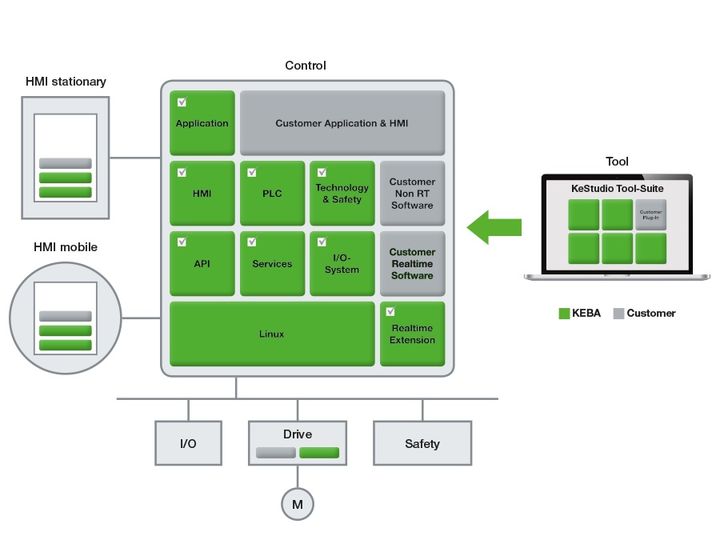

Thanks to the fusion of application-specific industry software with the innovative KEBA control system, an individual automation solution is created that is perfectly tailored to the target market. In addition, turnkey industry systems are available for HMI, plastics and motion & robotics, which can also be used.

Optimised to meet market requirements

Automation solutions from KEBA shine with numerous innovations.

Our modular software architecture allows you to choose freely which software modules KEBA uses and which you program yourself. Each new development can also be easily added to as a module at a later date.

Full concentration on core business - simple combination of own software and KEBA products:

- Reliable partnership with KEBA, expert support in every project phase

- Increased development potential without increasing staff

- Future-proof thanks to stable automation basis

- Life cycle management without risk

KEBA is involved in various committees, which aim at the standardization of Industry 4.0 technologies and the protocols used. New developments are therefore known at first hand and can be integrated promptly.

Already integrated Industry 4.0 topics:

- Remote Service

- Data logging

- Virtualization

- automatic optimizations

- Connectivity

- Support of Open Source platforms (e.g.: Node-RED, Grafana, InfluxDB)

The various expansion stages of our software platform Kemro X Runtime Basic, Real-Time and PLC, offer an ideal basis. Users select the required software modules from the desired system platform, integrate their own industry-optimised software modules and combine these with the proven KEBA system.

Your benefits at a glance:

- Individual automation solution within the shortest time

- turnkey industry systems for HMI, plastics and motion & robotics

- Highest flexibility

With the KEBA software solution, users no longer have to worry about basic automation, they can concentrate fully on expanding their own USPs.

Your benefits at a glance:

- Low-level APIs enable access to the complete control system

- HMI interfaces can be created easily, application-optimized and in accordance with the respective corporate design by means of drag & drop

- The engineering tools suite can be individually adapted and personalized

- The easy-to-use software supports the user with many intelligent wizards and templates

In order to meet all customer requirements, hardware components are available in different scales. In addition, different technology modules and expansion stages can be selected according to requirements.

Our control systems are suitable for every application due to the scalable hardware.

- Human Machine Interface for diagnostic functions and updates

- Security for maximum availability

- Standard PC interfaces (USB, PCIe, DVI, GBit)

- Compact and robust industrial PC

- Real-time process for reducing dead times (EtherCAT), SERCOS III

Our solutions

Individual drive systems for mechanical engineering

Our drive systems are the basis for performance, productivity and safety of your machine. The modularity as well as the wide range of products and services offered by KEBA drives guarantee you optimal and fast integration into the machine automation at all times.

- Flexible single-axis systems (24 Vdc-480 Vac with 2 A-450 A)

- Energy-efficient multi-axis systems (400-480 Vac with 1.5 A-210 A)

- Extensive range of motors

- Scalable safe motion solutions according to PLe/SIL3

This might also interest you

Software

Intelligent automation with powerful technologies

and the turnkey software solutions from KEBA.

Mobile HMI

KEBA handheld operating devices are the leading solution for mobile operation. You profit from the highest flexibility and efficiency.

Servo Motors

Engine competence:

With the various servo motor series you will find exactly the right motor for your machine.

Machine tools

KEBA has been automating machine tools to the highest satisfaction for 40 years and has its own CNC and robotics core.

Thank you for your request. Our KEBA Customer Support will get in touch with you soon.

Locations

Newsroom

Edge

Chrome

Safari

Firefox