KePlast Software Framework

High-performing technology for the plastics industry

The software makes the difference

Whether it be a single-board computer or a complex modular system, for hydraulic, hybrid or fully-electric injection molding or other plastics machines – all KePlast Systems are based on a fully scalable and innovative software platform. The KePlast Framework software is extremely portable. Programs that were originally created for an injection molding machine can run on other machines controlled by KePlast with different hardware without extensive adjustments needing to be made.

Quick and easy creation of applications

The comprehensive software and technology libraries for injection molding machines facilitate the quick and problem-free creation of various applications. In addition, this modern and state-of-the-art software package, with a Linux-based architecture, provides a stable and future-proof solution that is an absolute must-have for all future requirements of Industry 4.0.

Future-proof

An advantage with future-proof technologies

Openness

Open and modern software architecture

Competitive advantage

Quick time-to-market thanks to the ready-made framework

Individuality

Customization for all customer requirements

KePlast Software Platform

The advantages during the machine life-cycle

In all phases of the automation cycle, our KePlast software provides the

perfect support: From innovative software technologies and engineering and commissioning, through to the machine operation and production tools.

Alongside the innovative software technology, the KePlast framework also includes smart engineering tools and wizards.

Read more about the four software packages here:

- Innovative software technologies

The software framework is perfectly suited for all machine types including 2-platen and electric injection molding machines. It is also possible to use the latest communication technologies, such as EtherCAT and OPC UA, as well as modern control concepts with optimal support via FPGA hardware.

- Smart engineering & fast commissioning

The extensive tool suite guarantees a fast and guided creation of machine applications. Supporting wizards, such as KePlast AppCo for example, facilitate a fast commissioning of the machine and therefore a shorter time-to-market.

- Efficient operation

The focus is on the user when it comes to developing the KEBA visualizations. Top usability, modern gesture control and high-quality design form the basis of all KePlast user interfaces and guarantee shorter operating sequences and a distinctive face to your machine.

- Production tools & wizards

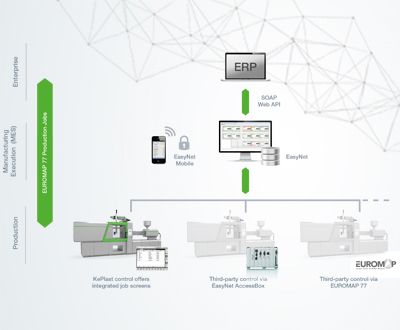

Tools to simplify the production processes and intelligent assistants support the machine operator in the optimization of their manufacturing. Planning tools such as the KePlast EasyNet MES or KePlast ServiceNet provide remote access so that the systems can be accessed from anywhere in the world and users can quickly be given the support that they need.

Innovative software technology

OPC UA information models

Intelligent software concepts form the basis for realizing any OPC UA-supported, generic information models. This means that standards such as EUROMAP interfaces are provided ready-made, but also that the realization of individual data structures and customer-specific data models is possible too.

KePlast Application Framework

The KePlast Application Framework provides comprehensive software and technology libraries for injection molding machines which facilitate a quick and problem-free creation of applications. The highly-modern and powerful software package with a Linux-based architecture provides a stable and future-proof solution which is even suitable for all future requirements of Industry 4.0.

Temperature and hot runner control

A high-quality temperature and hot runner control is an important component of complex injection molding machines. As well as a special hot runner technology module, the software also contains the necessary control components and the perfect integration into the KePlast visualization.

Hardware-based control concepts

The optimized interaction between KEBA hardware and the KePlast control components is key for perfect results. Intelligent FPGA hardware solutions facilitate a quick changeover point reaction with a reaction time of up to 62.5 µsec.

Quick engineering

We can commission your machine in just three days!

The unique KePlast design, with its finished software framework and intelligent tool support, helps to ensure extremely efficient engineering workflows. Our modular, open and powerful KePlast software can either be used as a turnkey solution or as an ideal starting point for customer-specific further developments and for the realization of their specific SPS and HMI requirements. This way, plastics machine manufacturers can ensure a quick time-to-market and therefore gain an advantage over their competitors.

Efficient machine operation

KeView Style is the modern visualization framework that can be used to create all multi-touch interfaces. This framework stands out from the crowd as it uses the latest technology and offers a range of special features, such as a modern gesture framework, guided wizards for the user, simple navigation and top usability of operating elements.

Navigate into the future

The user is the focus

The multitouch screen panels on the KePlast series are setting new standards when it comes to usability. A smooth workflow with intuitive multitouch gestures facilitates an extremely quick setting of process values and reduces the time needed for the mold validation of new forms and the operating sequences in day-to-day production.

State-of-the-art technology with KeView Style! The modern and Java-based HMI framework is based on the latest software technology and offers multimedia functions, HTML 5 online help, a PDF viewer, videos, and much more. The clear and modern design is incredibly user-friendly and the openness of the software makes it easy to create individual operating concepts that are tailored to your machine.

Simple configuration of machine sequences

Quick, easy, versatile

The KePlast Machine Sequencer is a user-friendly graphic software assistant that supports users in creating or adjusting machine sequences. Thanks to its intuitive operation and visually appealing interface, the machine sequence programs can be adjusted quickly and affordably by Drag&Drop and with no prior knowledge of programming needed. The sequence of all machine movements is fully flexible and makes it easy to quickly set up of new tools.

The Machine Sequencer is ideal for use with injection molding machines that have complex sequences, multiple injection units or alternating machine options, as well as for applications with complex forms and alternating core puller sequences.

Individual parameter display

Intuitive and individual

In an intuitive guided editor, the user can design an individual dashboard directly in the visualization. The desired parameters can be selected from a list of the available process parameters and put together in a dashboard page via Drag&Drop. The user can choose the page structure that they want and where to place the values. The tailored screen pages massively reduce the operating sequences, therefore leaving the user free to concentrate on any frequent and repeated adjustment work.

Graphic profile editor

Optimized and user-friendly

There is a convenient graphics editor that can be used to configure machine movement profiles. In this editor, profile points can be added or moved via Drag&Drop. It turns optimizing machine movements into child’s play. In order to ideally cater to each user’s individual needs, alongside the graphic editor there is also an option to enter the data manually in a table.

Intelligent tools & wizards for the end customer

In order to maintain an optimal productivity and utilization of all plastics machines, the focus is primarily on the end user. Tools to simplify the sequences for machine operators and intelligent assistants, such as KePlast ServiceNet for quick remote support or KePlast EasyNet MES as a convenient tool to monitor the entire production process, support the user.