Creating automation solutions. Together.

Under the motto “Creating automation solutions. Together.”, we show how innovative technologies and collaborative partnerships are shaping the future of industrial automation.

From modular control systems to comprehensive automation concepts, we work alongside you to develop flexible, scalable and future-proof solutions. For every industry and every challenge.

Meet our experts in person and let's turn your automation vision into reality together.

📍 Booth 470, Hall 7

📅 November 25-27, 2025

We look forward to seeing you there!

Thank you for visiting us at SPS Nuremberg!

Creating automation solutions. Together – under this motto, we would like to express our sincere thanks to all visitors. Your conversations, feedback, and enthusiasm made our trade fair appearance something very special.

Discussing new approaches to automation, exchanging ideas, and addressing specific challenges facing tomorrow's industry. It was a great pleasure for us, and for that we say “THANK YOU.”

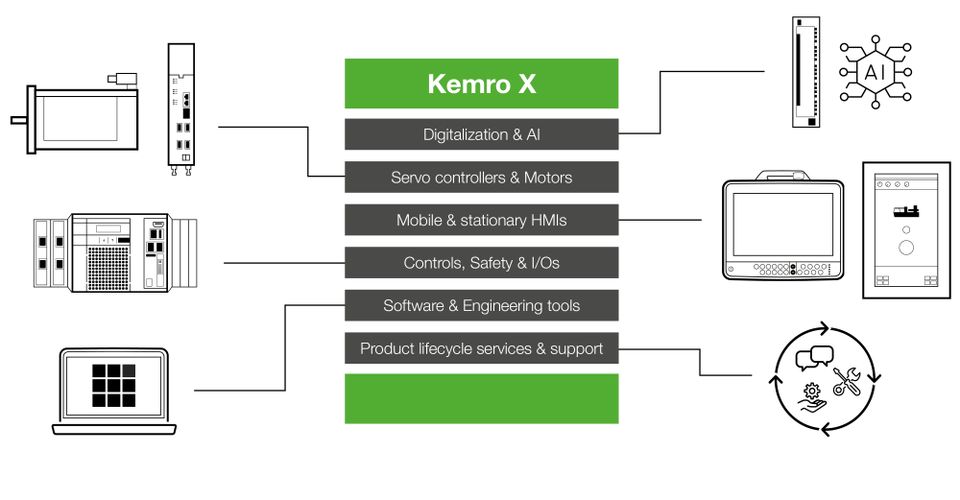

Shaping the Future Together with Kemro X

Creating automation solutions. Together.

Experience how ideas are generated when working together at SPS Nuremberg. With our open and modular automation platform, Kemro X, we collaborate to design flexible, scalable systems that are perfectly tailored to your needs. It is open to third-party integration and ready for the industry of tomorrow.

Our trade fair highlights

...stay tuned...

Our trade fair highlights

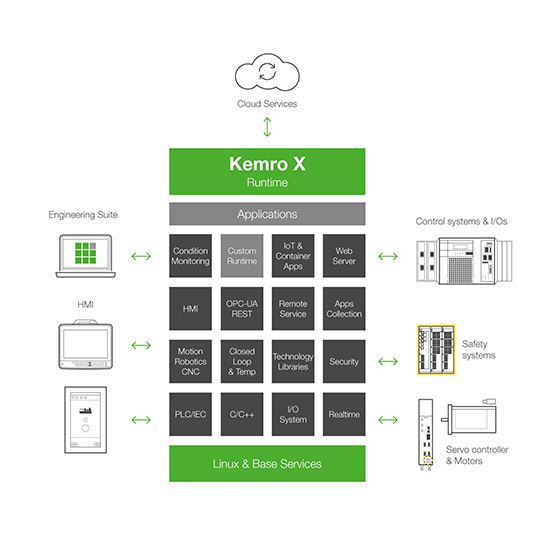

Open system architecture

Thanks to its open architecture and standardized interfaces, the Kemro X Runtime Software can be individually expanded with your own software modules and third-party applications.

Deep integration of robots

With Kemro X and KeMotion, we integrate robots and machines on a single control basis – for seamless processes, greater efficiency, and data-based maintenance.

Digitalization & AI

Get to know our 360° Digitalization & AI Portfolio. It goes beyond automation, adding value to every phase of the machine or plant lifecycle.

Scalable Drive Technology

From single-axis to multi-axis systems – KeDrive D5 and D3 servo controllers combine precision, dynamics, and seamless integration into various automation setups.

Mobile and wireless operation

Compact, flexible, and PROFINET/PROFIsafe-compatible—the new KeTop T135 and the KeTop Safe Wireless set new standards in mobile HMI operation.

Integrated safety technology

Our KeSafe safety technology solutions include hardware and software for the safe operation of machines and robots in accordance with current standards and guidelines.

Find more information on our product pages or download data sheets or brochures from our SPS download platform:

Our Impressions of SPS 2025

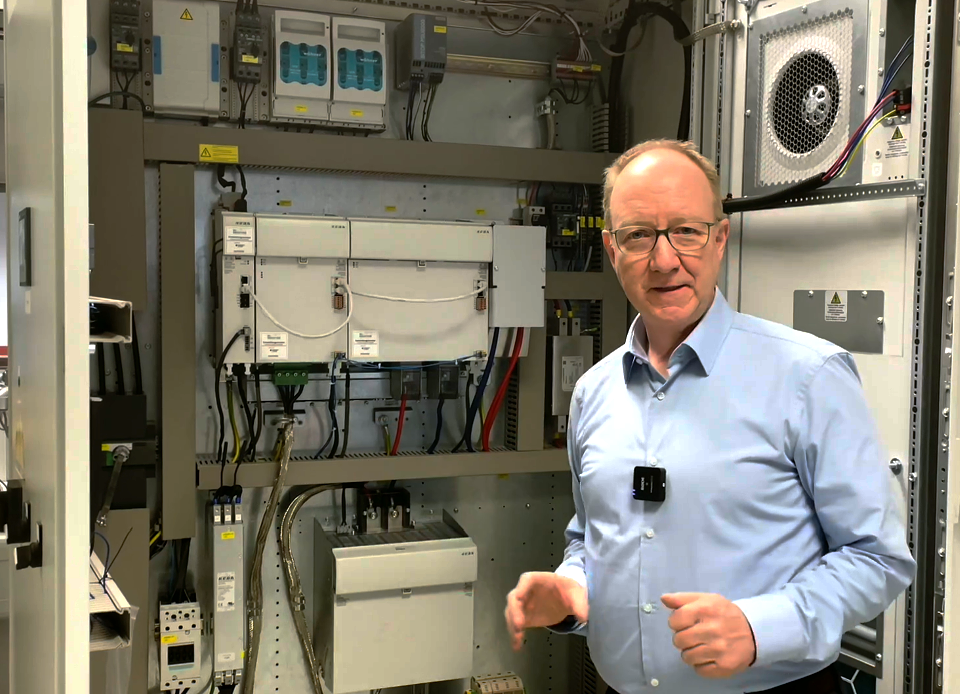

Kemro X demonstration

Our hardware and software components can be combined in a versatile and uncomplicated way. Using the example of our live demonstration at the SPS, we will show you a comprehensive automation solution with Kemro X.

It includes four KEBA technology highlights: Robotics for pick-and-place applications, our AI module, the wireless operating solution KeTop Safe Wireless and the KeDrive D3-AC drive system, which is used in machine modules with only a few axes and enables efficient energy exchange and energy storage.

Presentation on the

SPS stage in hall 1

Efficiency and grid failure protection with energy storages in the drive system

Who? Jörg Brinkemper, Strategic Product Manager Drive Solutions

When? November 26, 2025 | 11:40 a.m. – 12:00 p.m.

Where? Hall 1–250

In industrial automation, drive systems account for up to 70% of energy consumption. If you want to boost energy efficiency, this is where you need to start. With the KeDrive D3 Smart DC System, we offer a solution: integrated directly into the drive system, it enables energy savings, peak load reduction, use of renewable energy, and safe, controlled machine shutdown.

Make an appointment with our experts at SPS Nuremberg and get your free ticket.

Thank you for your request. Our KEBA Customer Support will get in touch with you soon.

Locations

Newsroom

Edge

Chrome

Safari

Firefox