Drive solutions for wind turbines: FAQs

- Windenergy

- 17.2.2023

- Reading Time: {{readingTime}} min

Contents

What does KEBA do in the wind sector?

KEBA has more than 25 years of experience and can provide a wide variety of references in the field of electromechanical pitch controllers and yaw systems for onshore and offshore wind turbines.

KEBA is the original manufacturer of the pitch drive controllers—previously known by the brand names Lust Antriebstechnik and LTI Motion—and continues to supply the entire range of products for the older PitchMaster product series.

Still under the name of LUST/LTI Motion, KEBA started adapting standard electronic systems used in drives to rugged environments and tailoring new developments to such applications. Even at extreme climatic conditions between -40 °C and +70 °C ( -40 °F and +160 °F) and installation at elevations up to 3,000 meters (9,800 ft), these solutions were able to ensure the optimal exploitation of the wind energy.

Today’s pitch drives include a multitude of application-specific hardware and software features specially made for reliable pitch control. The dynamic synchronization of multi-axis solutions permits the implementation of smart control concepts for yawing and saves space in the control cabinet at the same time.

Since the introduction of wind turbines with active pitch control, KEBA has been supporting leading wind turbine manufacturers in the optimization and continuous development of their systems. More than 120,000 pitch solutions are already in operation around the globe.

What does KEBA do differently in the wind sector?

KEBA relies on equal partnerships and long-term cooperation. To this end, KEBA creates key account teams in the company who cooperate closely with customers. These team members talk directly to the relevant point of contact on the customer side. For example, if the customer's application engineer needs to discuss any technical issues, they can talk directly to KEBA’s application engineer without having to go through the sales representative or anyone else first. This allows for quick, professional consultation with an open, cooperative customer focus.

Many of the world’s leading wind turbine manufacturers have been partnering with KEBA in this manner for years, with great success. This approach requires a special kind of quality management with in-depth knowledge of the history of various products, diagnostic data, batch tracing, etc.

KEBA products are making wind turbines safer and more compact. In addition to compliance with applicable requirements stipulated by Germanischer Lloyd and TÜV, the use of functional safety allows for new solutions that reduce components with TÜV-certified performance level PLd (PLe according to ISO13849 at system level. KEBA products of the latest generation (PitchOne) support Ple; older models such as PitchMaster II+ support PLd.

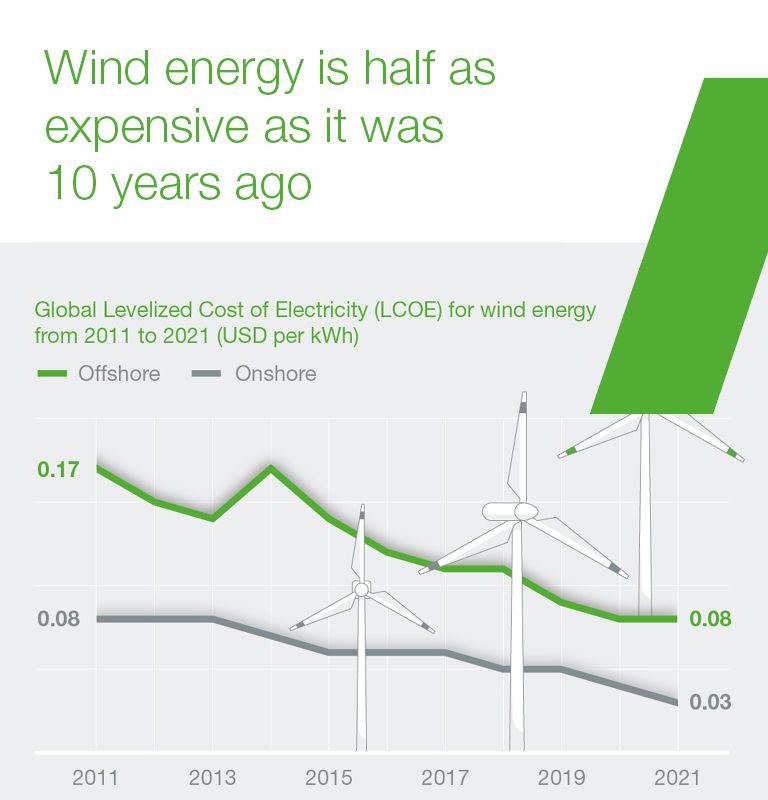

In order to reduce turbine costs and the levelized cost of electricity (LCOE) and to speed up development, external components are built into the device. This also helps customers achieve a faster time-to-market.

Does KEBA offer yaw drives and solutions?

We offer innovative solutions for yaw systems that are based on our comprehensive modular automation approach. The KeDrive D3 multi-axis drive system provides the basis for a fully electric yaw drive that increases the wind turbine performance in the long term.

Multi-axis drive systems with closed-loop control have become the standard for yaw systems because of their efficiency and their benefits compared to conventional concepts.

Another important factor with regard to yaw systems are the long-term operating costs for end customers who need to run an efficient wind turbine. For this reason, KEBA yaw systems rely on a low-wearing control concept that keeps maintenance and follow-up costs as low as possible.

| Azimut Leistungsübersicht KEBA | |

|---|---|

| Multi-axis system | |

| Low-wearing control concept | |

| High performance range | |

| Multi-Encoder interface | |

| Active energy recovery | |

| Safety function | STO |

| OPC UA | |

| Flexible automation concept | |

| Multi-motor technology |

Does KEBA offer end-to-end pitch systems (including energy storage and pitch box)?

KEBA offers important components for pitch systems such as drives, converters, and motors, which have the flexibility to implement diverse specific system philosophies (architecture with 3, 4, 6 or 7 pitch boxes).

In addition to the active cooling systems that are common in the market, KEBA also offers a passive cooling solution. Passive cooling is unique in the market and made possible by a fan-less design. Flexible integration in the control cabinet and the rotating hub is supported.

KEBA is not active in the areas of „energy storage“ and „control cabinet production“. Energy storage products can be procured from other suppliers such as „Skeleton“.

Does KEBA also offer pitch converters?

KEBA PitchOne is the leading technology product in pitch drives. This pitch servo drive is now in its 5th generation with more than 25 years of market experience.

The DC boost function allows engineers to reduce the size of motors and energy storage devices and ensures reliable conditions for the drive system.

PitchOne’s integrated Linux platform with Codesys functionality provides for outstanding functionality and flexibility. The Profinet interface represents a significant performance increase in data transmission compared to the commonly used CAN communication; however, the latter is also supported by PitchOne. This means that the pitch system does not require a separate controller.

In addition, certain peripheral components are no longer needed, such as line chokes or redundant safe rotary encoders for the pitch angle (encoder in the toothing of the rotor blade bearing). One KEBA customer was able to realize savings of 20 percent at the system level.

Does KEBA also offer pitch motors?

KEBA pitch motors are adapted to the demanding operation in wind turbine installations and stand out for their high power density.

The design of PitchOne and of the motor ensures the full utilization of the drive system’s power potential. Optimal fine-tuning is achieved through cooperation based on the customer’s simulation data.

| KEBA pitch system feature overview | |

|---|---|

| Drive | |

| Motor | |

| Energy storage | - |

| Converter | |

| Pitch box (3 or 4) | |

| Pitch box (6 or 7) | |

| Backup power topology | UC, Lion, Lead |

| Cooling systems | passive/active |

| Fan-less design | |

| TÜV certification | |

| Motor qualification | |

| HIL simulation | |

| Model-driven development (MDD) | |

| Control cabinet production | - |

| End-to-end systems | - |

| Sizing consultation | |

| Certified safety-oriented development (V-model) |

Generally KEBA takes over all repairs of its own products

What is the process for KEBA equipment repairs, and how is customer service organized for the wind sector?

KEBA operates its own repair centers in Germany (Lahnau), China (Shanghai), and India. PitchMaster and PitchOne devices are repaired directly at these repair centers.

Because KEBA is the original manufacturer of pitch drive controllers that were previously marketed under brand names LUST Antriebstechnik and LTI Motion, the entire range of PitchMaster products for wind turbines sold using these old brand names is available for purchase, and technical support can be provided (with the exception of Drivestar devices: KEBA will assist customers with finding a solution within the KEBA partner network.)

All repair centers use original spare parts as well as inspection and testing equipment from the production line. This guarantees the excellent quality of our repair work.

As a rule, KEBA takes care of repairing all of its own products. Even in a scenario where a third-party component turns out to be defective, KEBA will handle the repair job, thus saving customers any additional effort.

For more information on spare parts and repair services for wind turbines, go to this page: Spare parts for Wind turbine installations