Pitch control and yawing: systems for optimal wind turbine design

- Windenergy

- 1.9.2025

- Reading Time: {{readingTime}} min

Contents

Note: This article and the figures contained therein were updated in August 2025.

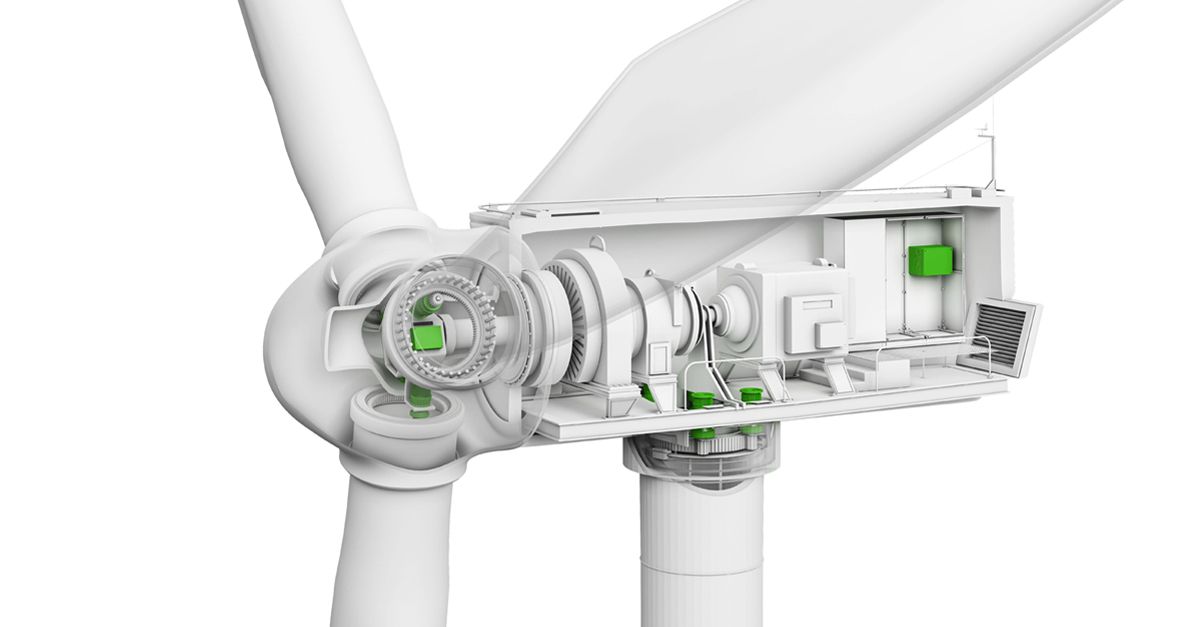

Wind turbines – complex systems with high efficiency potential

The development and commissioning of modern wind turbines requires more than favourable wind conditions. Factors such as grid connection, legal framework, infrastructure and security concepts have a significant influence on profitability.

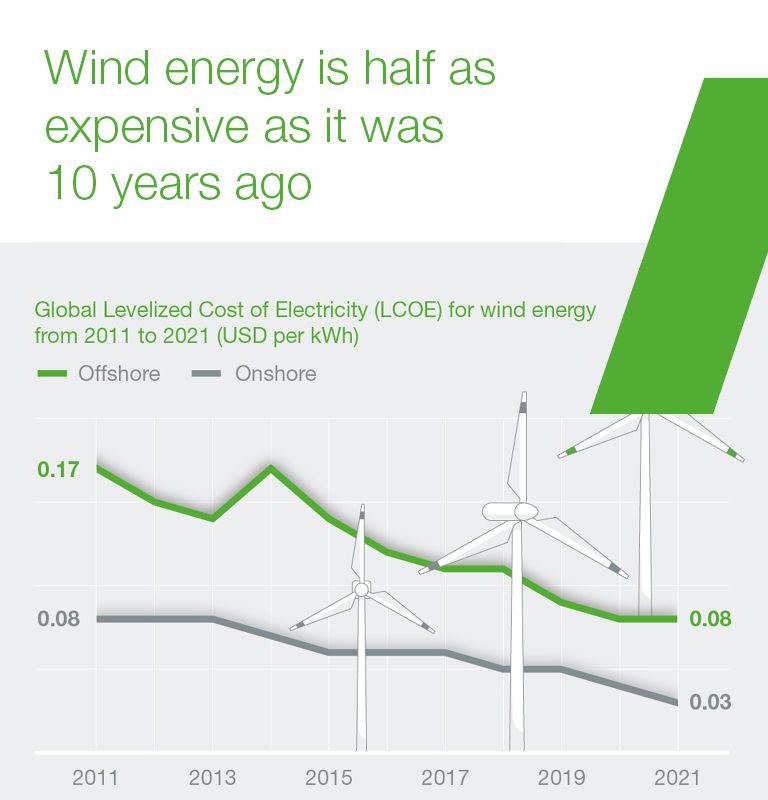

Technological progress and the growing demand for performance pose new challenges for OEMs and operators: The plants are getting bigger, the operating times are longer and the pressure to reduce the levelized cost of electricity (LCOE) is increasing. According to the Fraunhofer ISE Study 2024, the LCOE for onshore wind in Germany is already 4.3–9.2 ct/kWh and is expected to fall further by 2045.

This is where pitch control and yaw systems come into play: they precisely control rotor blades and the nacelle and are crucial for energy yield, safety and longevity. In this video we explain exactly how the pitch and yaw movements work.

Pitch systems: efficiency, safety and longevity

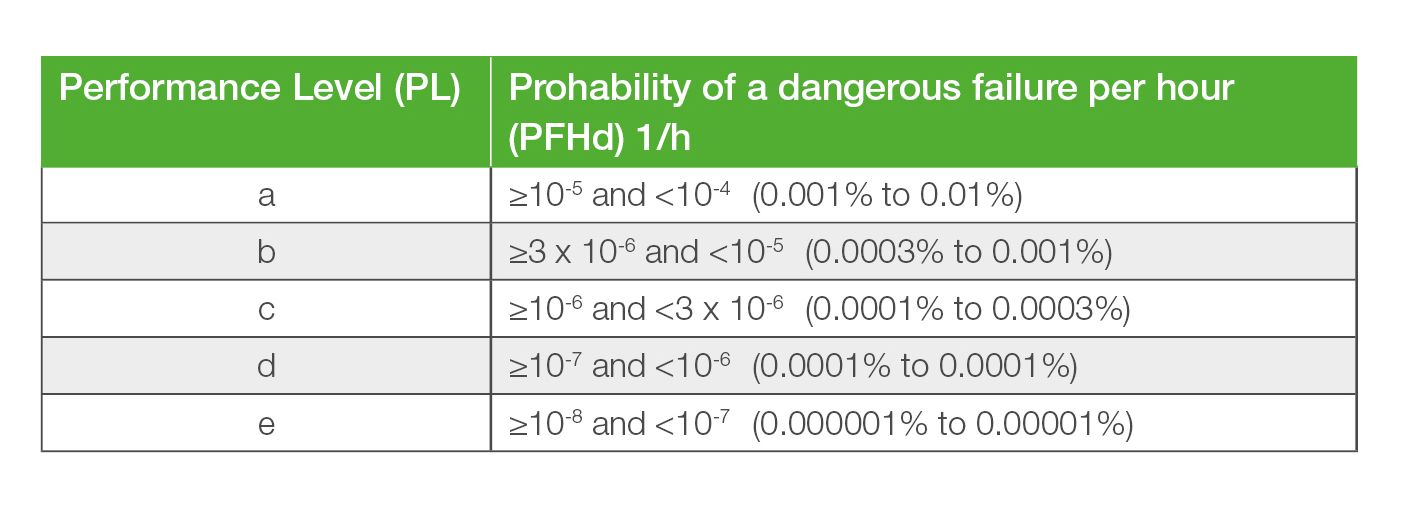

Modern pitch systems, such as our PitchOne, regulate the angle of attack of the rotor blades and at the same time take over the function of the main brake. Thanks to certified safety components (Performance Level e), digital simulation and modular architecture, the use of materials is reduced and system availability is increased.

The Performance Level (PL) in the table describes how reliable a safety-related system is in relation to dangerous failures. It comes from the EN ISO 13849-1 standard, which is often used in mechanical engineering to evaluate safety-relevant controls. Switching from PLd to PLe means that the system becomes even safer – with a 10x lower risk of dangerous failure per hour. However, this improvement also requires greater technical and organizational effort.

In order to meet the increasing size and power of wind turbines, the PitchOne product family was expanded in 2024: With the new PitchOne Size1+, a version with 25-30% increased power density1 is now available. It is specially designed for larger turbine types that require higher drive torque. At the same time, the development of the PitchOne Size 2 was launched, which is specifically designed for onshore and offshore turbines in the range of 6 to 15 MW.

The PitchOne product extensions enable OEMs to rely on the proven technology platform even with increasing system output – including safety certification, modular design and maximum flexibility in engineering2.

These technological advances lead to a decisive cost advantage over the entire service life of the turbine – a key lever for reducing the levelized cost of electricity (LCOE), as predicted in the Fraunhofer ISE Study 2024 for onshore wind power at up to 3.7 €cents/kWh.

Cost advantages of electric pitch systems – at a glance

Material savings

- Reduced tower vibrations due to profiled safety travel → lower fatigue loads.

- Allows for thinner steel walls, lighter components, and smaller fasteners. The use of PitchOne can lead to a reduction in power components of up to 20%.

Fewer mechanical components

- No mechanical main brake required – aerodynamic braking via pitch system.

- Less maintenance and fewer wearing parts.

Optimized energy yield

- Precise control of the angle of attack → maximum efficiency in changing wind conditions.

- Higher annual energy yield (AEP) through continuous performance optimization.

Lower operating and maintenance costs

- No hydraulic fluids, filters or accumulators.

- Integrated condition monitoring enables predictive maintenance.

Advantages in retrofit and new systems

- Easy integration into the wind turbine

- Reduced installation time due to modular design and standardized components. For instance, with PitchOne, the assembly time of the PitchBox, including energy storage, is reduced by 50%, from 5 hours to just 2.5 hours, compared to the PitchMasterII+ without energy storage.

Pitch-controlled cut-in and cut-out wind speed

The central control system of a wind turbine continuously monitors the wind speed and dynamically adjusts the angle of attack of the rotor blades via the pitch system. The aim is to keep the system in the optimum operating range at all times.

- In very light winds – typically below 2.5 m/s – economical operation is not possible. In this case, the rotor blades are brought into an idle mode to keep the turbine idle and minimize mechanical stress.

- In the range of medium wind speeds, for example between 12 and 25 m/s, the pitch control ensures that the rotor blades are adjusted in such a way that the lift force is reduced. This allows the rated output of the system to be kept constant without overloading.

- In very strong winds – from about 25 m/s – the system is finally switched off for safety reasons in order to avoid mechanical overload due to overspeed. In this case, the pitch system brings the rotor blades into a flag position, which slows down the rotor aerodynamically.

In summary, pitch systems allow aerodynamic deceleration of the rotor without a mechanical main brake, thus ensuring a constant and optimal speed. This reduces torque fluctuations and contributes to an overall quiet operation. Pitch and YAW systems thus make a decisive contribution to the performance, safety and durability of modern wind turbines.

Pitch control and azimuth systems ensure the best possible performance of wind turbines.

Yaw systems: Precise nacelle control through dynamic synchronization

Yaw systems take over the wind direction tracking of modern wind turbines. They ensure that the nacelle is always aligned exactly in the direction of the prevailing wind. This allows the rotor to be optimally flowed, which has a direct effect on the energy yield.

Today, the technological standard is controlled multi-axis drive systems, such as our SmartYAW solution based on the KeDrive D3 platform with dynamic synchronization. These systems distribute the mechanical loads evenly over several drives and enable particularly gentle acceleration and deceleration of the nacelle movement.

Advantages over conventional concepts:

- Uniform load distribution reduces mechanical wear on gearboxes, bearings and the tower

- Higher energy yield due to constantly accurate wind tracking

- Reduced reaction times to changes in wind direction through fast, coordinated movements

- Hydraulic brake system can be dispensed with, thus reducing maintenance costs

A particularly economical advantage results when a hydraulic brake system can be dispensed with. This not only reduces the weight and complexity of the system but also saves maintenance costs and consumables. However, the prerequisite for this is an early integration of the Yaw system into the overall safety concept of the wind turbine.

In addition, modern drive systems such as KEBA SmartYaw offer high power density, active energy recovery and precise feedback via robust encoders. This combination not only increases operational reliability and availability but also prevents cost-intensive downtimes. With a typical lifespan of 20 to 25 years, this is a crucial factor in the overall profitability of a wind turbine.

Conclusion: More performance with less effort

Wind turbines are among the most cost-efficient technologies in the energy mix today. Their LCOEs makes them a central component of the energy transition and a competitive alternative to conventional power plants. However, these costs are highly dependent on the respective site conditions, such as wind frequency, tower height and turbine size.

In order to ensure maximum energy yield and constant grid feed-in under these conditions, modern pitch and YAW systems are used. They ensure that the rotor blades are always at the optimum angle of attack and that the nacelle is precisely aligned with the wind direction. This not only makes the system more efficient, but also mechanically protected.

These systems make a significant contribution to extending the service life of the equipment, reducing maintenance costs and avoiding expensive downtime. At the same time, they enable precise control in changing wind conditions and optimized power output, which has a direct positive effect on the LCOE.

1 depending on the parameter being considered.

2 If you would like to learn more about how intelligent software solutions in wind turbines help to reduce the material load on the turbine and thus reduce costs, read our article: How can software features contribute to the safety of wind turbines?