Systematically improving robot accuracy – from mechanics to compensation

- Robotics

- 7.10.2022

- Reading Time: {{readingTime}} min

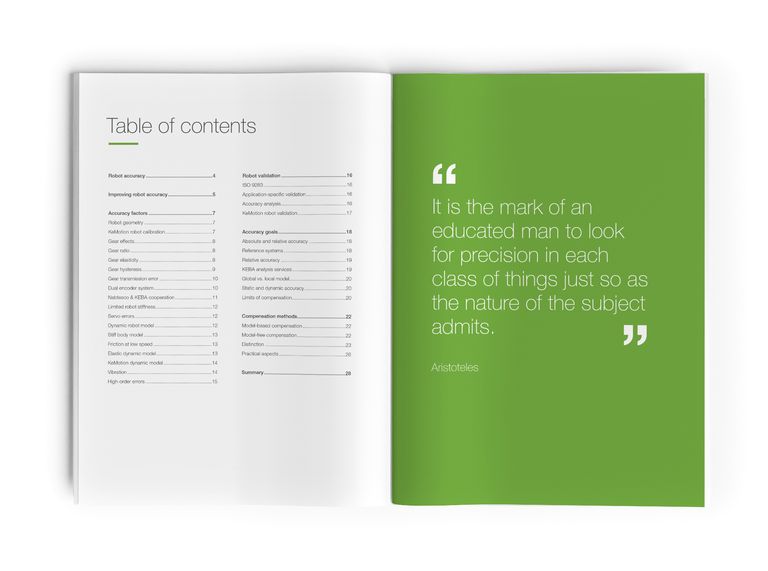

Contents

Precision as the key to new applications

Today, industrial robots perform tasks where precision is not only a quality feature but also an economic necessity. Applications such as laser processing, high-precision assembly, 3D printing, and coating processes require deviations in the range of less than ten micrometers. Path deviations below 1 mm are now state of the art for medium-sized precision robots, but they are by no means the limit of what is technically feasible.

The central question is therefore no longer whether robots can be precise enough, but how this precision can be achieved in an economical, robust, and reproducible manner.

From the mechanical ideal to the real system

For many years, robot accuracy was primarily improved through increasingly precise mechanical components. High-quality gearboxes, tight manufacturing tolerances, and rigid structures formed the basis for this. However, this approach is increasingly reaching its physical and economic limits.

Modern robots are not rigid systems. Elastic gears, compliant bearings, flexible robot arms, and dynamic effects during movement mean that real-world behavior differs significantly from the ideal design model. Added to this are changing loads, friction effects, and vibrations. Today, accuracy is no longer achieved exclusively through mechanics, but through the interaction of mechanics, control, modeling, and measurement technology.

Key factors influencing robot accuracy

The achievable precision of a robot can essentially be attributed to a few dominant influencing factors:

Robot geometry: Small errors in lengths or axis angles add up along the serial kinematics and lead directly to TCP deviations.

Gear effects: Elasticity, hysteresis, backlash, and periodic transmission errors (gear ripple) are among the biggest accuracy drivers. Load changes and direction reversals are particularly critical.

Limited stiffness: Not only gears, but also bearings and robot arms deform under load. These effects are load- and position-dependent.

Calibration and models at the next level

Traditional robot calibration primarily improves static accuracy by adjusting geometric models. Modern approaches go further and also take into account:

Load-dependent gear elasticity

Dynamic effects during movement

Friction at low speeds

Variable workpiece and tool masses

Dynamic robot models make it possible to calculate the required motor torques in advance and significantly reduce servo tracking errors. Feedback remains necessary, but is now only used to correct model deviations and disturbances.

New chapter compensation methods deals with how the effects can be controlled in practice.

New chapter in the updated white paper:

Targeted use of offsetting

With the newly added chapter “Compensation Methods,” the white paper “Robot Accuracy” significantly broadens its focus. The focus is no longer solely on analyzing factors that influence accuracy, but also on the systematic question of how these effects can be controlled in practice.

A central idea of modern accuracy strategies is: Don't model everything, but identify what is relevant. Models that are too complex with many parameters are difficult to identify reliably and quickly lose their validity outside the measuring range. The aim is therefore to identify the dominant sources of error and compensate for them in a targeted manner.

The chapter compares three basic approaches:

Model-based compensation: Physical and mathematical models take into account the geometry, elasticity, and dynamics of the robot. They are particularly suitable for improving absolute accuracy and at high speeds, but require precise parameterization and measurement effort.

Feedback control loop: Control approaches react to deviations in real time and can also compensate for unmodeled disturbances. However, their effectiveness is limited by bandwidth and measurement technology.

Iterative learning control (ILC): For repetitive processes, learning approaches offer the highest potential for accuracy. Deviations are not only reduced, but actively avoided. In practice, accuracy improvements of up to an order of magnitude are possible, but only with sufficiently reproducible processes.

Validation as a basis for optimization

Die ISO 9283 bietet einen wichtigen Referenzrahmen zur Vergleichbarkeit von Robotern. Für hochpräzise Anwendungen ist sie jedoch nur ein Ausgangspunkt. Entscheidend ist die anwendungsspezifische Validierung. Genauigkeit hängt stark von Arbeitsraum, Geschwindigkeit, Bahnform und Last ab. Erst gezielte Messungen entlang realer Prozesspfade zeigen, welche Effekte tatsächlich limitierend wirken und wo Optimierung sinnvoll ansetzt.

Toolset for robot validation

The KEBA robot controller includes an integrated toolset in the control software with the tools needed for quick and reliable robot validation. KEBA’s control software can even run on a PC, without any robot. The motion controller simulates not only the setpoint movements but also the robot dynamics as well as the robot behavior.

This makes it possible to examine in advance the forces, moments, and drive currents that occur as well as any deviations caused by controller behavior and gear elasticity. The simulation tools thus help fine-tune the overall mechatronics systems, paths and sequences for greater accuracy. Likewise, users have the option of simulating their core processes in the control system. This allows them to view the overall solution consisting of robotics and process as a whole. Risks during the processing of orders can be avoided from the outset, and even exceptional situations can be mimicked without any expense or risk in order to verify how the system responds.

Conclusion: Understanding, evaluating, and specifically improving robot accuracy

High-precision robotics is no longer achieved through maximum mechanical perfection alone. The key lies in:

Intelligent calibration

Realistic models

Targeted compensation

Systematic validation

Anyone who wants to increase robot accuracy economically must understand mechanics, control, and measurement technology as an integrated overall system. This is precisely where it is decided whether micrometer precision remains achievable in the real process or only exists on the data sheet.