The robotics platform that frees teams from thinking like automation specialists

- News

- References / Success Stories

- Robotics

- 19.9.2024

- Reading Time: {{readingTime}} min

Contents

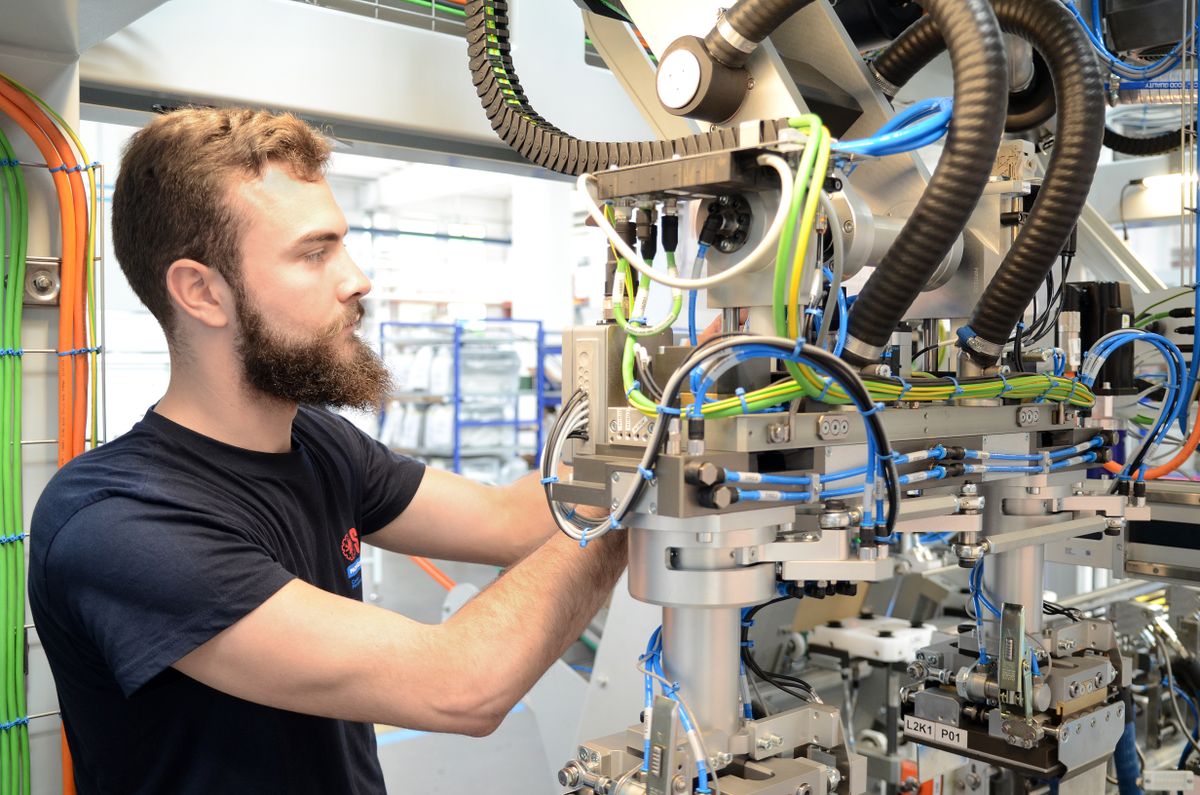

SACMI is an international group and the world’s leading supplier of advanced technologies for the ceramics, plastics, food & beverage, metals, packaging and advanced materials sectors. Headquartered in Imola, Italy, the group has nearly 5,000 employees. SACMI Packaging & Chocolate S.p.A. is part of the SACMI group: it provides major food brands with manufacturing solutions and close support in the packaging and chocolate areas, making it one of KEBA’s ‘sweetest’ business partners. What follows is the story of how KEBA helped SACMI Packaging & Chocolate take their robotics strategy to the next level.

Flexibility matters

Close cooperation between SACMI Packaging & Chocolate and KEBA began in 2020 when the former decided to look into the opportunities offered by KEBA’s new open robot platform for high-speed pick & place operations, which offers high performance and top-notch service.

After a convincing concept presentation, a laboratory test was agreed upon. Enrico Vivaldo, a lead engineer with the SACMI Packaging & Chocolate R&D department, says: “I was truly surprised by the result. The KEBA solution is flexible and genuinely open: it’s the only one on the market that lets us implement industrial robotic kinematics, including non-conventional ones, at such high levels of performance. Moreover, we believe it to be the system closest to the industrial robot approach: it lets us think and program like a robotics team, not an automation team. This saves lots of time during planning and construction and adds huge flexibility to our solutions.”

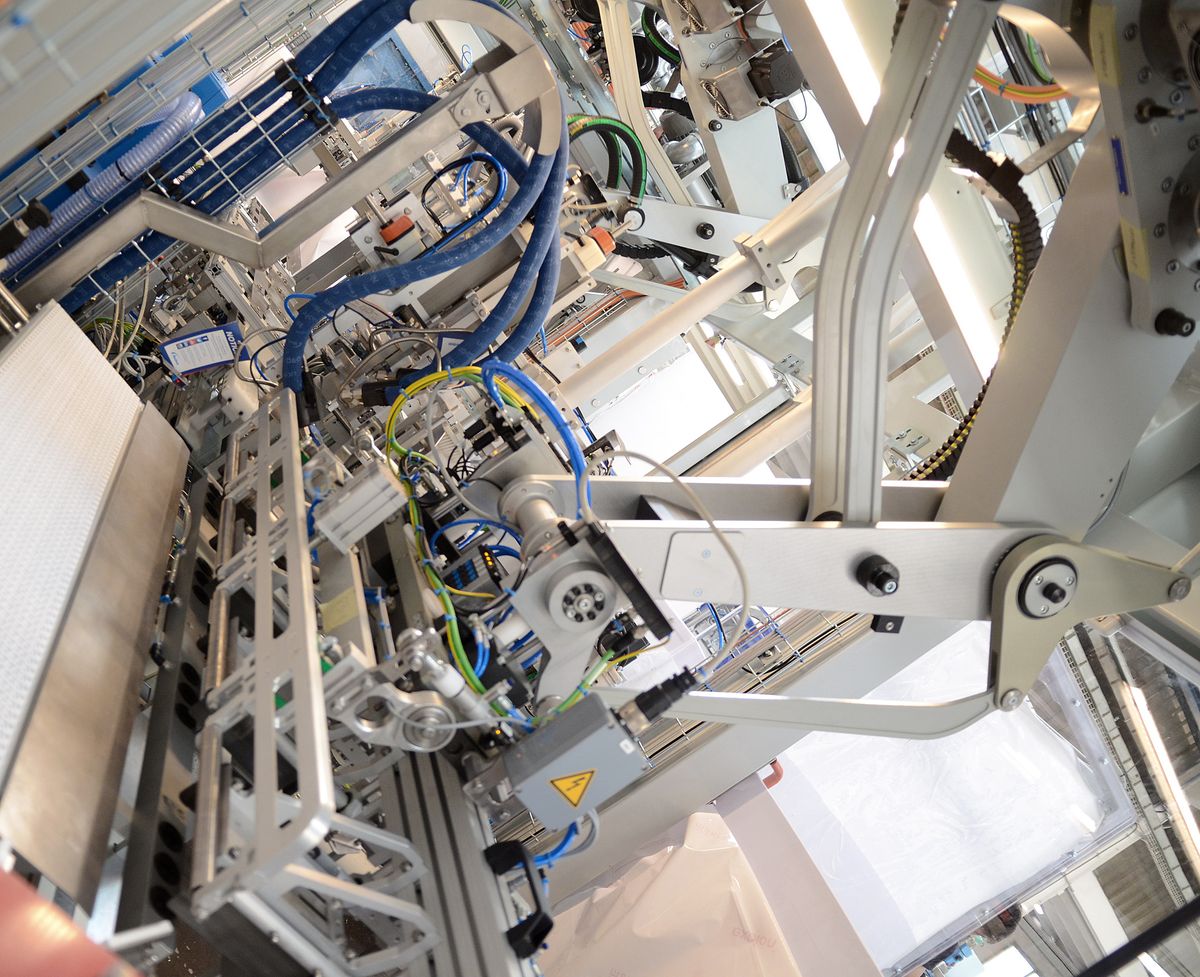

The KEBA platform lets users openly select the robot kinematic required, a feature standard robotic platforms do not completely offer. This system allows to have a decentralized architecture when more controllers are needed.

Facts matter

Vivaldo and his team were able to make a fact-based decision: the KEBA solution proved to perform better than solutions from other motion/robotic suppliers. “The kinematics are much smoother and much more precise, which increases the picks per hour by 10 to 15 percent”, Vivaldo adds. Consequently, a first line was soon established, with a second one following (with a shorter start-up time). At present more lines with this configuration are operational. Results have confirmed the test outcomes, ensuring excellent reliability and performance in day-to-day operations. Hence SACMI’s decision to start introducing the KEBA solution in much bigger robotics installations too, deploying more than 30 robots within a single system.

"The KEBA platform lets us think and program like a robotics team, not an automation team."

KEBA can easily handle non-standard robotic kinematics without us having to program from scratch. KEBA allows us to manage a wide range of tasks, using just one or multiple robots.

Challenges in the packaging industry matter

The packaging market of the future is going to require the highest flexibility and performance.

Vivaldo: “Our ‘stress point’ is that we need to use many different kinds of kinematics and robot brands to fulfill the complex tasks high-end customers demand of us. Until recently, we focused on delta robotics only”. The KEBA robotics platform supports several ready-to-use kinematics in multi-robot environments. Modular at both hardware and software level, it allows customers to design line concepts without being limited by the maximum number of robots that can be used. “This ready-to-use robotics, in combination with a high-level motion system, has a vast application range,” adds Vivaldo. “We needed to find an architecture that would let us assemble easily with a ready-to-use robotic layer in combination with the ability to create simulations of entire robotic lines but without the need to interrupt production to do so”. This also revolutionized SACMI’s pre-sales process, where it’s necessary to predict performance and behavior before the solutions are actually built. “With the KEBA system, this is greatly simplified and we can develop outstanding, innovative solutions while being confident they will reliably solve the customer’s task once completed,” Vivaldo points out.

Future matters

Vivaldo and his team describe KEBA Industrial Automation as an Austrian company with an Italian mindset that makes things easier for their business partners. In short: a solid basis for future projects. Technical talks have shown the two companies are decidedly on the same wavelength. “We can see that KEBA has vast in-house experience. We’d like to extend usage of the KEBA platform to other strategic applications, mainly in secondary packaging”, states Vivaldo.

Further development of their solutions will focus on sustainability of both the machines (energy savings and so on) and the used material (eco-friendliness).