Optical grinding

Precision meets experience

With decades of experience—starting with the Andronic control system—KEBA offers a highly developed CNC solution for the optical grinding of lenses.

Specially optimized motion commands for convex and concave geometries enable precise contour tracking. The CNC core is designed for minimal block change times, ensuring maximum machining speed and efficiency. Machine builders benefit from a comprehensive feature set designed for maximum precision and productivity.

Your benefits at a glance

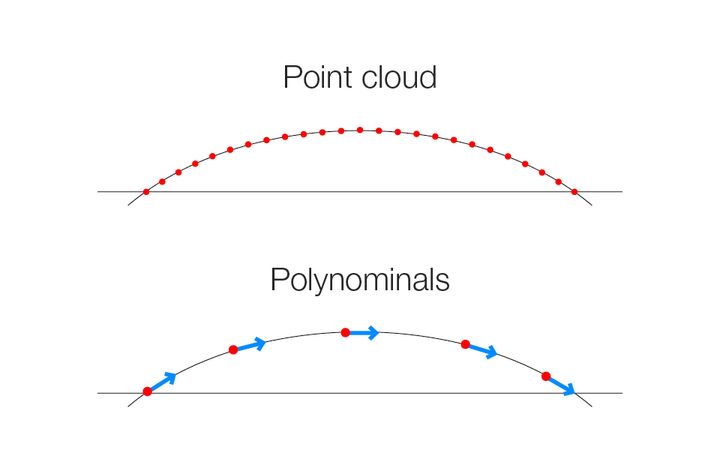

- G-code extensions for polynomials of 3rd and 5th degrees to follow concave/convex geometries as accurately as possible

- Quality data collection based on integrated target/actual comparison across the entire process

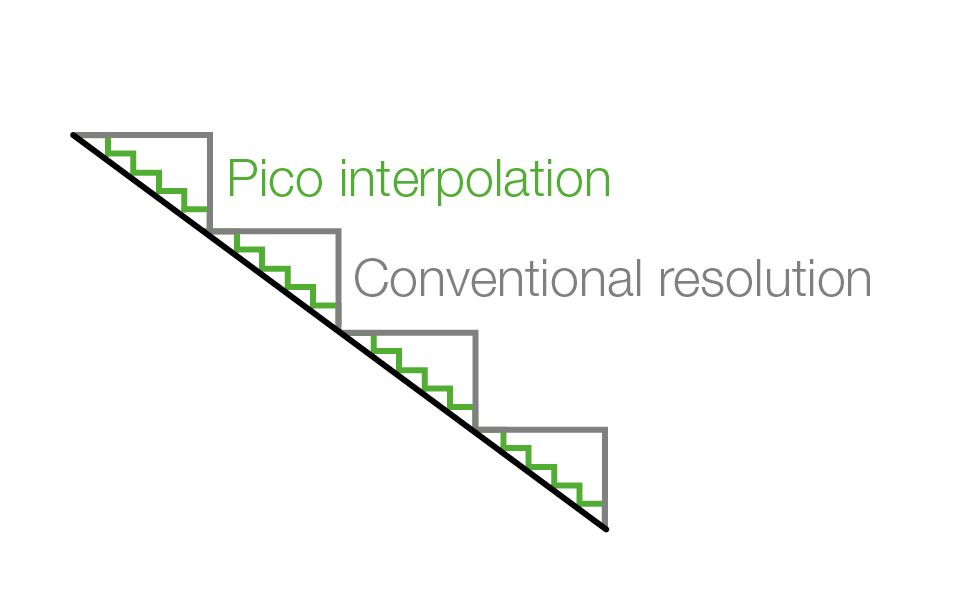

- Fast setpoint specification for precise contours (up to 8 kHz) with pico interpolation

- Process data feedback into running CNC program

- Adaptive control to increase clock rate

Flexibility in CNC programming

Customized CNC solution for every application

The KEBA CNC solution gives machine builders freedom of design when it comes to programming. Depending on the task, different, optimally coordinated solutions are available at different levels. Whether complex geometries, high dynamics, or special motion cycles – our CNC platform offers the right answer. Here is an overview of the options we offer:

Our CNC solution goes beyond the standardized G-code command set and offers targeted enhancements for demanding applications. Especially when machining convex and concave geometries, 3rd and 5th degree polynomial functions enable mathematically precise path control. The CNC core supports these commands natively, allowing high-precision contours to be achieved with minimal programming effort.

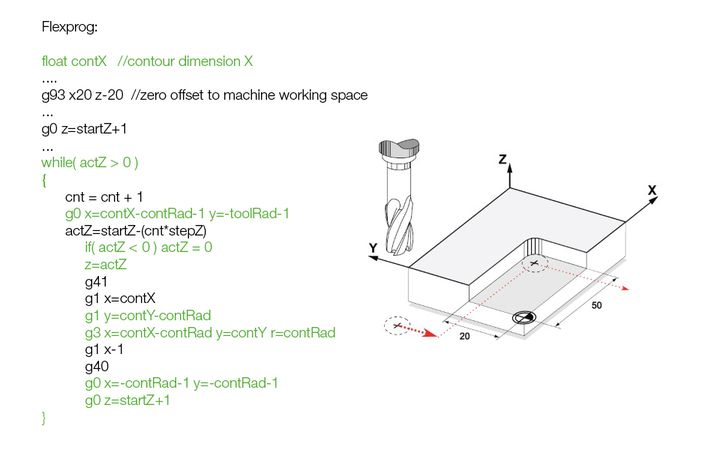

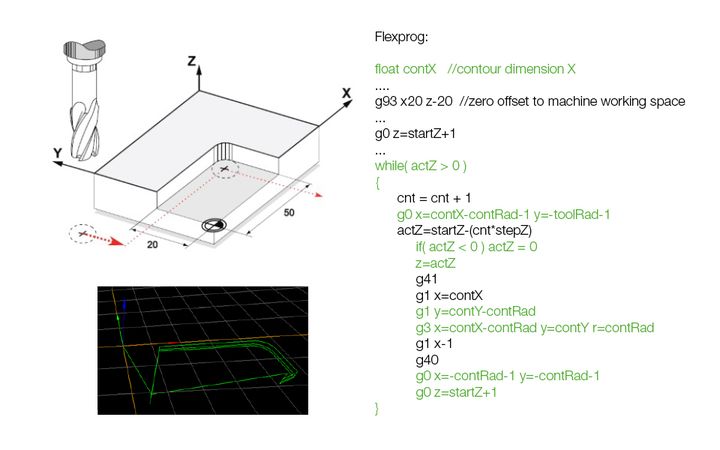

With FlexProg, you can expand your CNC programming with powerful elements of modern high-level languages—directly in G-code. Instead of pure parameter programming, you have access to structured programming constructs such as loops, conditions, procedures, and variables. Even complex mathematical expressions can be implemented efficiently. This not only significantly reduces implementation time, but also increases the readability, maintainability, and reusability of your programs. FlexProg enables modular and flexible programming—ideal for complex machining strategies and customized automation solutions.

The integration of a slim Lua interpreter into the Kemro X-CNC opens up completely new possibilities in CNC programming. Complex machining cycles can be created more easily, data and file processing becomes more efficient, and string manipulation is also effortless. Programming is convenient in development environments such as Eclipse LDT or KeStudio cppEdit—including syntax highlighting and input support. This means that individual cycles, such as a custom homing cycle, can be implemented quickly and easily. Lua makes CNC programming more flexible, powerful, and intuitive.

Pico interpolation

With pico interpolation, our CNC solution sets new standards in position accuracy and motion control. Instead of the usual 32-bit setpoint transmission, position data is transferred in an extended 64-bit format. The drive regulates at 8 kHz and, thanks to the more precise setpoint specifications, can operate much more dynamically and with greater contour accuracy. The result: precise path tracking and improved surface quality – ideal for demanding applications in optics, precision engineering, and micro-machining.

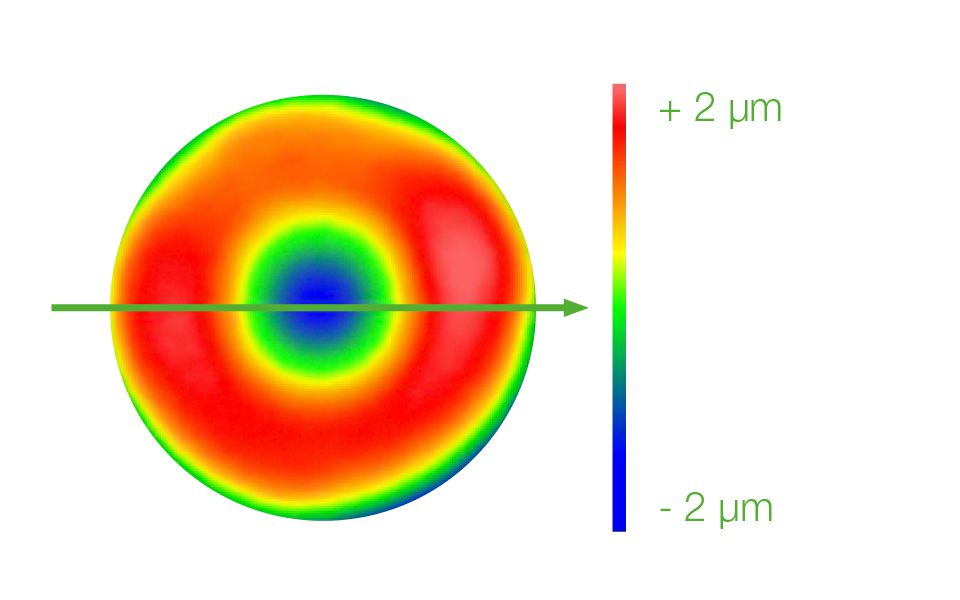

Quality data collection

With our CNC system, you can record drive data directly in the PLC task with a cycle time starting at 500 µs – for high-resolution and real-time quality analyses. The actual values are documented in the position log and compared with the target values, enabling precise evaluations to be made across the entire 3D surface of the workpiece. Thanks to integrated dry-run simulations, processes can be optimized as early as the engineering phase. This ensures quality, increases efficiency, and shortens development times.

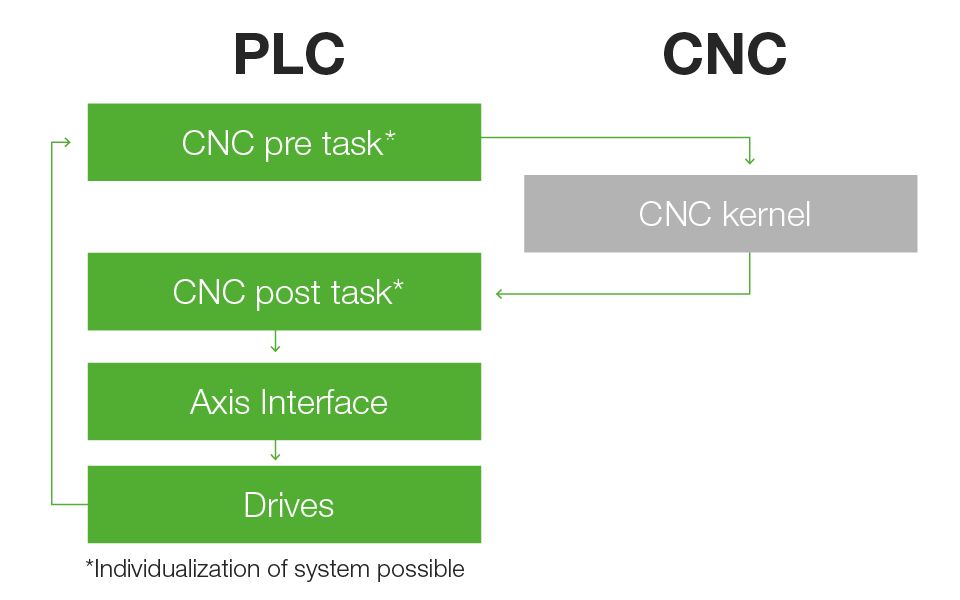

Data exchange - NC and PLC synchronized

Our CNC solution is integrated into the automation platform via powerful interfaces and enables clock-synchronous data exchange between the NC core and PLC – for maximum responsiveness during the running process. Process data such as position deviations or torque changes can be fed directly back into the CNC program and processed there flexibly. This enables adaptive control strategies to be implemented, for example for fast movement to surface contact. Your advantage: significantly higher cycle rates, increased efficiency, and a new dimension of process intelligence.

This might also interest you

CNC functions

Perfectly matched software and function modules ensure the future-proof digitization of your machine in a single system.

HMI solutions

A separate customized visualization underlines the strengths of your machine tool and improves its usability.

Controllers

For all requirements: Standard controllers, control and drive systems with safety control, or optimized controllers with onboard I/Os

Servo controllers

KEBA’s ServoOne product family offers a wide variety of servocontrollers for drive systems, ensuring optimum machine process integration.

Locations

Newsroom

Edge

Chrome

Safari

Firefox