Tool grinding

Your benefits at a glance

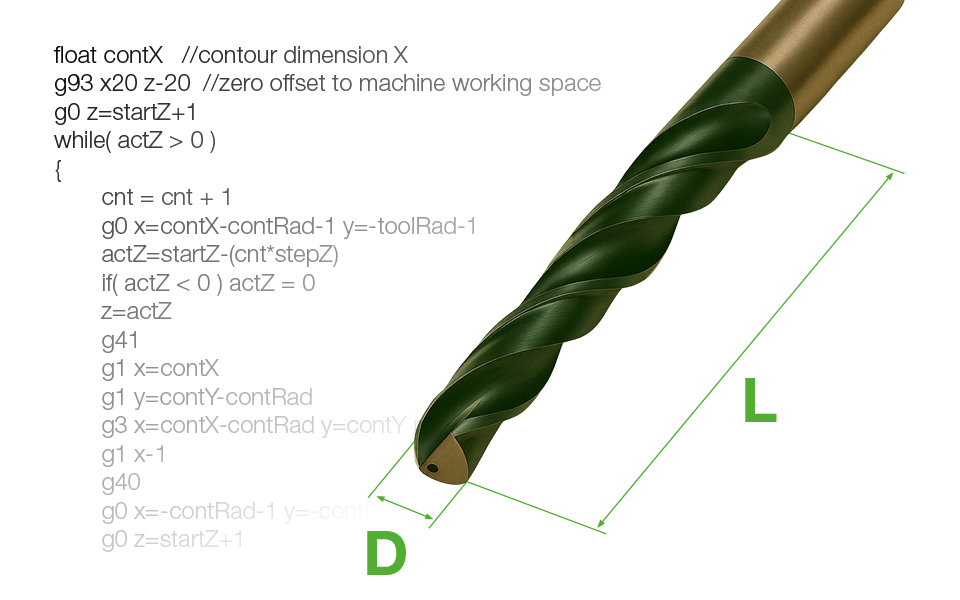

Our CNC control system impresses in the field of tool manufacturing thanks to its high level of flexibility. The modern programming of our system allows the integration of our own CAM systems into the automation process.

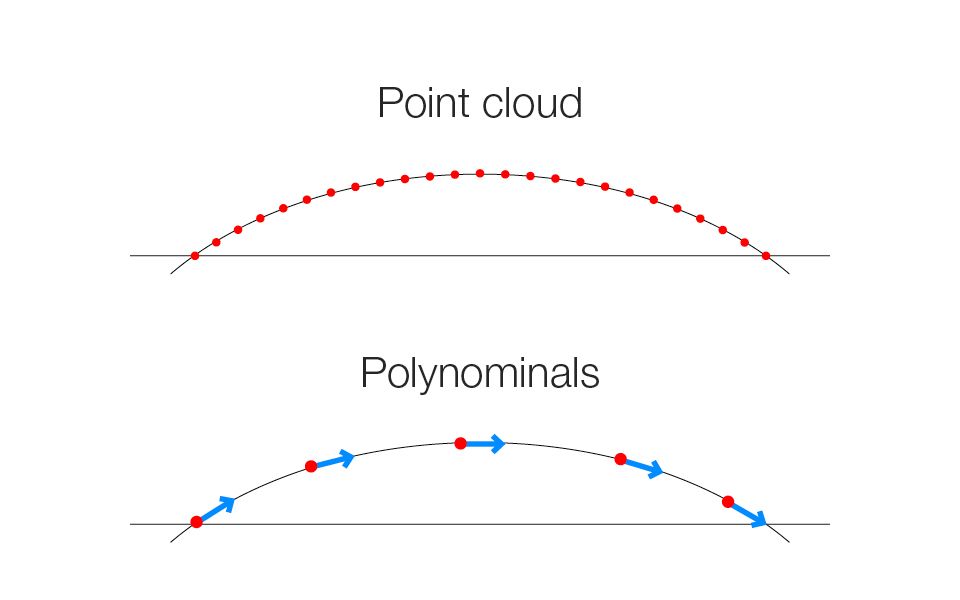

- G-code extensions for polynomials of 3rd and 5th degrees enable complex path geometries

- Pico interpolation for smoother running

- Adaptive control to increase clock rate

- Custom cycle programming via LUA and Flexprog

- Integration of CAM systems

- Fast cycle time thanks to pre-translated NC programs

Optimal connection to CAM system

Seamless integration of CAM systems is a crucial factor for efficient manufacturing processes. With the Kemro X CNC system, you have complete control: it offers you several connection options, allowing you to freely choose the one that best suits your requirements.

Efficiency rethought

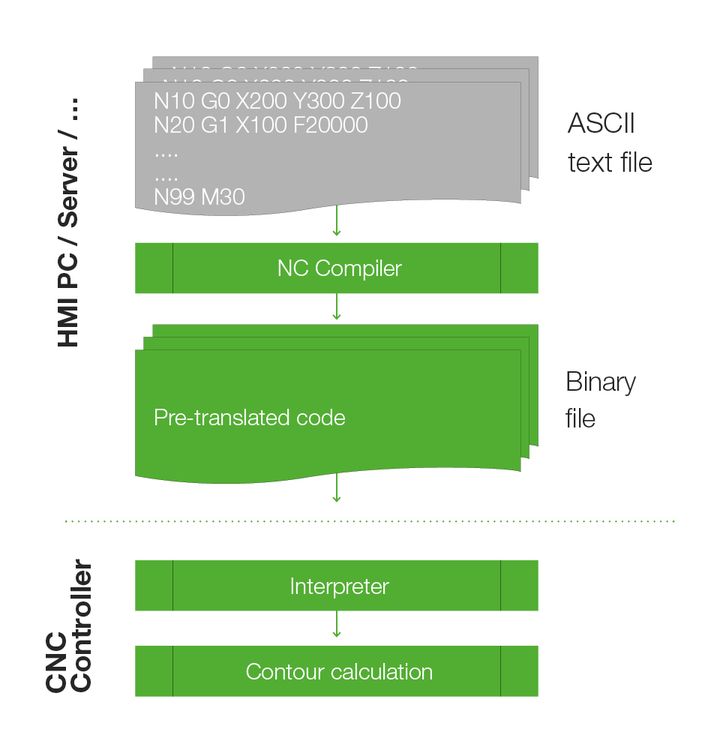

G-code programs can be pre-translated into binary code using our NC Compiler. The syntax check is performed directly in the NC Compiler.

The CNC processes the pre-compiled G-code directly and without detours – the result: significantly faster processing of your programs and thus a performance gain in production.

Real-time control redefined

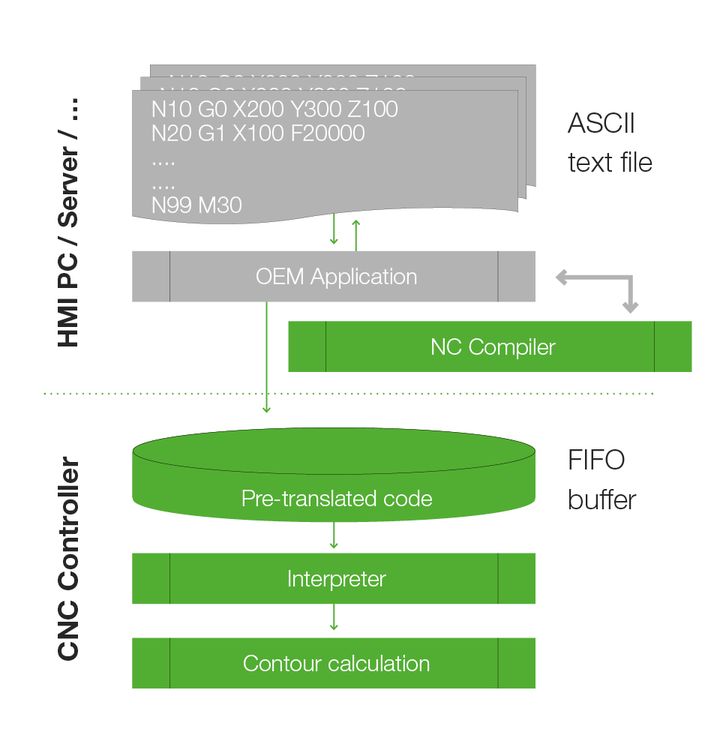

With its online interpolation data operating mode, the Kemro X CNC system offers a powerful option for real-time control of your manufacturing processes. The precompiled G-code is written directly to a FIFO buffer memory in the CNC – ready for immediate processing.

Thanks to suitable interfaces, the CNC can be seamlessly integrated into your higher-level OEM application. This takes over the “remote control” of the controller and enables the dynamic transfer of contour blocks in real time. After processing the individual contour block, processing is automatically stopped.

Your advantage: Maximum flexibility in data transfer, fast response to process changes, and a CNC that responds immediately to your control commands – for maximum precision and efficiency.

Real-time control at maximum speed

With Fast Online Interpolation, the Kemro X CNC system offers a high-performance solution for direct control of your CNC processes. The buffer memory is controlled entirely by your OEM application, which “remotely controls” the CNC controller in real time.

The application sends the desired G-code programs directly to the compiler, which processes them immediately and forwards them to the CNC controller. The controller implements the data without delay – for fast, precise, and flexible machining. Processing starts as soon as the first commands arrive at the controller.

Your advantage: Direct communication, fast response times, and maximum efficiency—ideal for demanding manufacturing processes with dynamic requirements.

Improved path generation

By supporting polynomial processing, we replace classic G1 movement commands with polynomials. The result: significantly smoother path control that minimizes jerking and thus ensures superior surface quality.

Thanks to smooth transitions and precise path tracking, you benefit not only from higher drive dynamics, but also from improved path accuracy—even during complex machining processes. Kemro X CNC thus enables manufacturing at the highest level while increasing the efficiency of your machines.

Adaptive control with Kemro X CNC

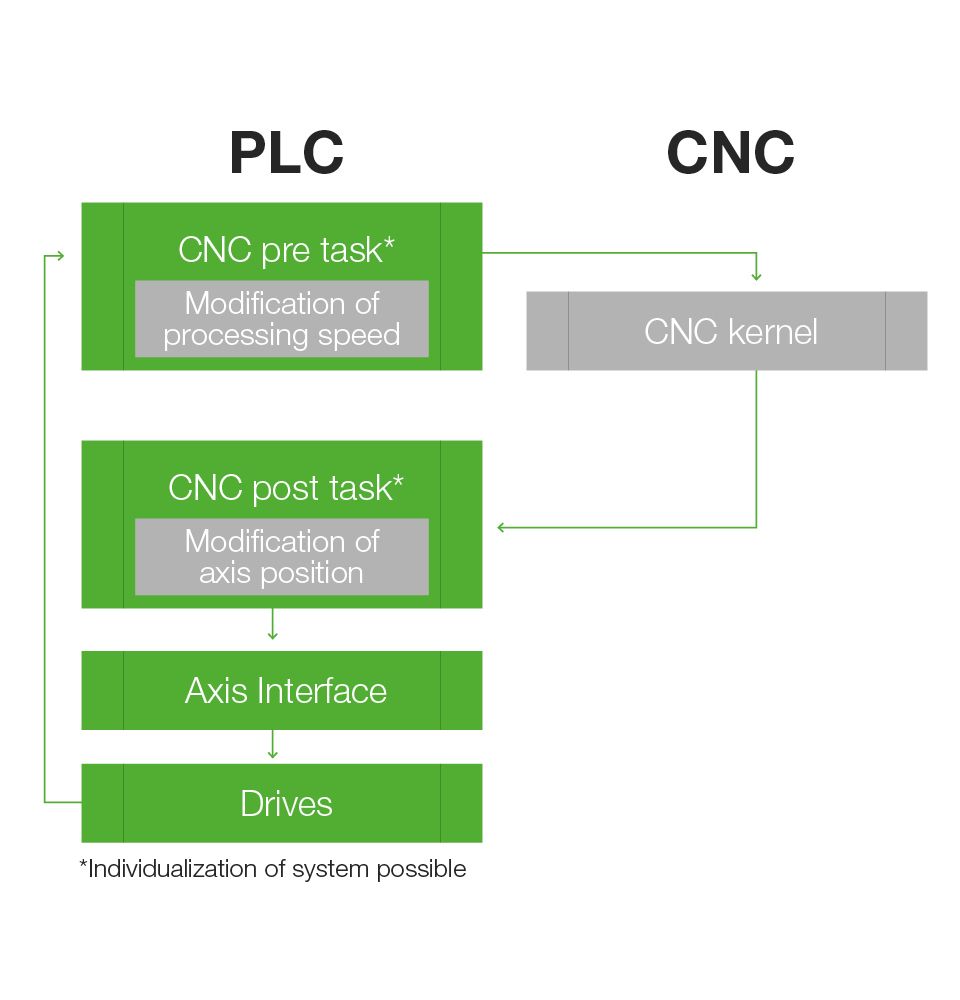

By incorporating our Kemro X CNC core into the PLC world in an optimal way, we are laying the foundation for adaptive process control—controlled by the machine application. Machine builders can respond specifically to process events in the CNC cycle and dynamically adjust the machining sequence.

A typical example: If the grinding wheel becomes clogged, the torque of the spindle drive increases. This information can be used in the application to reduce the feed rate and then start a dressing cycle. This extends tool life and improves machining quality – individually and according to requirements.

Kemro X CNC provides the technical basis – the machine application can respond flexibly.

This might also interest you

CNC functions

Perfectly matched software and function modules ensure the future-proof digitization of your machine in a single system.

HMI solutions

A separate customized visualization underlines the strengths of your machine tool and improves its usability.

Controllers

For all requirements: Standard controllers, control and drive systems with safety control, or optimized controllers with onboard I/Os

Servo controllers

KEBA’s ServoOne product family offers a wide variety of servocontrollers for drive systems, ensuring optimum machine process integration.

Locations

Newsroom

Edge

Chrome

Safari

Firefox