Kemro X - Industrial Automation Platform

This was KEBA at the SINDEX in Bern

This year we showed how flexible and individual modern automation can be. The components can be combined as required to create exactly the right solution for the company in question.

With a wealth of experience, high-quality technologies and proven concepts, we have already successfully implemented numerous automation solutions.

Thank you for visiting us at SINDEX in Bern!

Your KEBA team

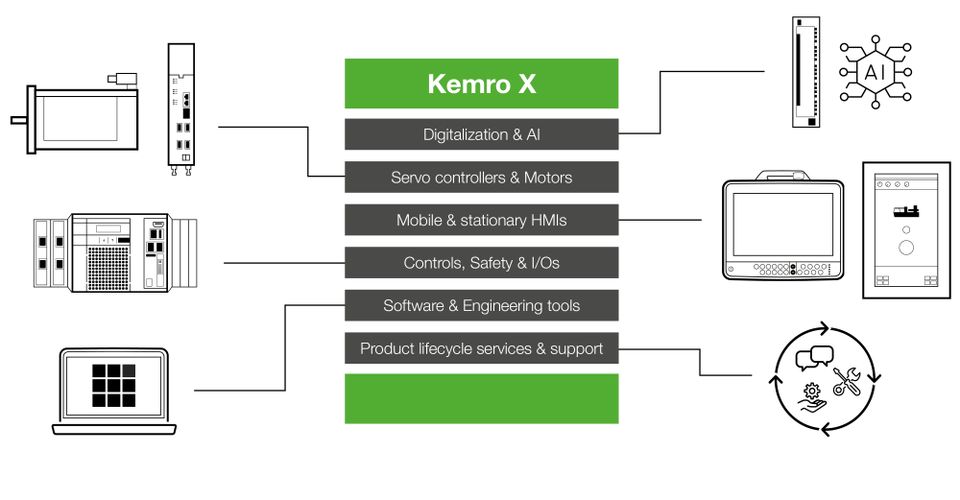

Create your own automation solution

Automation to suit your taste

The components of the Kemro X product & service portfolio can be flexibly combined with each other to create a holistic solution for industrial automation. thanks to the open system architecture and standardized interfaces, 3rd party components can be easily integrated into Kemro X.

Our trade show highlights at a glance!

New: Product Configurator Drives

Configure your optimum drive solution with just a few clicks. Discover how easy it can be - with or without a selection guide. In addition to the Drives Configurator, you can also try out our successful HMI Configurator directly on site.

New: KeDrive D5 – Single-axis controller

The new single-axis controller offers compact solutions for drive applications with a small number of axes. Ideal for machine, device and apparatus construction

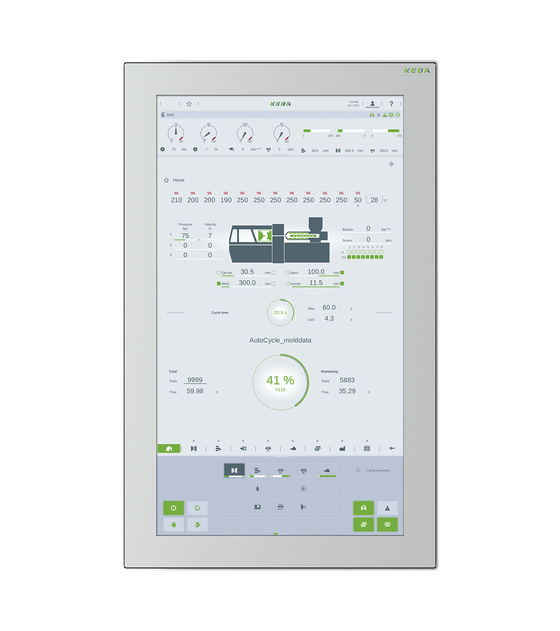

KeTop Safe Wireless

Easy operability through multitouch and safe machine operation

- Ergonomic and customizable operation

- Intuitive HMI design with high usability

- Robust hardware in portrait or landscape format

KeTop AP500

Robust gesture operation using industrial multitouch with integrated touchbooster for glove operability

- Real-time control of machines

- Haptic feedback

- Customizing of hardware and software

KeDrive D3 - Drive system

Compact multi-axis drive system with integrated safety technology

- Compact design

- Safe movements in the axis controller

- Simple integration of existing systems

Milon Biceps Curl – Live testing

Experience the precision of our control technology live. Train on the Milon fitness machine and feel the difference.

- Simple & safe - with live feedback

- Effective - thanks to the electronic resistance

Automation changes - Our world and that of our customers

We at KEBA are proud every time a customer project is successfully completed. In our Lookbook we show you selected success stories.

Why do we do it? We would like to take you with us into the diverse world of industrial automation and show you what opportunities are available. In the cooperation with our customers, partnership is particularly important to us, because our solutions do not start with our know-how, but with the needs of our customers.

Why is it worth reading the stories from the KEBA world? They were exciting joint projects that are worth writing down and seeing. Dare to look beyond the industry and experience what can happen when you meet at eye level to develop solutions.

It was also about turning your ideas into reality.

Didn't you have the opportunity to discuss all your ideas with our automation experts on the booth? Or are there new ones that you didn't think of until now? Then do not hesitate to contact our team in Switzerland directly!

We thank you for your visit at SINDEX 2023 in Bern.

Hopefully, you had a good time there and were able to discover our latest highlights.

Locations

Newsroom

Edge

Chrome

Safari

Firefox