Spindles

Tailor-made spindles from KEBA and Heinz Fiege

Spindle technology

Heinz Fiege GmbH is part of the KEBA Group and has been a supplier of precision tool spindles with mechanical bearings for over 50 years. We focus in particular on analyzing the specific application requirements in order to be able to offer the optimal custom solution.

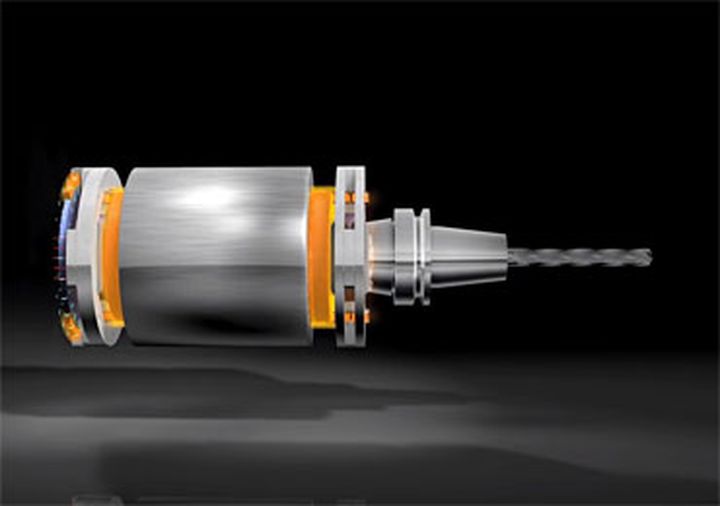

KEBA has been active in the field of magnetic bearing technology for over 20 years. Its Levispin R140 is a 3rd-generation magnetic bearing spindle. An oscillation motion superimposed over the feedrate creates outstanding possibilities, such as increasing the processing speed by more than 200 % and reducing the tool wear to below 50 %.

Overview of our powerful spindles

Tailor-made spindle technology for perfect solutions in grinding technology, and magnetic bearing spindles for revolutionary advances of the drilling process.

Modern machining technology requires powerful, dynamic spindle drives.

Benefits:

- High precision and long service life

- Optimal adaptation to customer needs

- Condition monitoring

The vibration-assisted 6D drilling with a magnetic bearing spindle creates an entirely new drilling process. This creates shorter drill chips and less burr and at the same time achieves improved process speeds and drill hole quality. The built-in sensors additionally provide for intelligent process monitoring with material detection.

Benefits:

- Increased productivity

- Increased drill hole surface due to minimized friction from very small drill chips

- Process optimization

- Intelligent process monitoring

Thank you for your request. Our KEBA Customer Support will get in touch with you soon.

Locations

Newsroom

Edge

Chrome

Safari

Firefox