Who is the automation platform suitable for — and when is it not suitable?

- Digitalization

- 3.2.2026

- Reading Time: {{readingTime}} min

Contents

Missed Kemro Xplained Part 1? Click here for the blog article

Who is Kemro X suitable for?

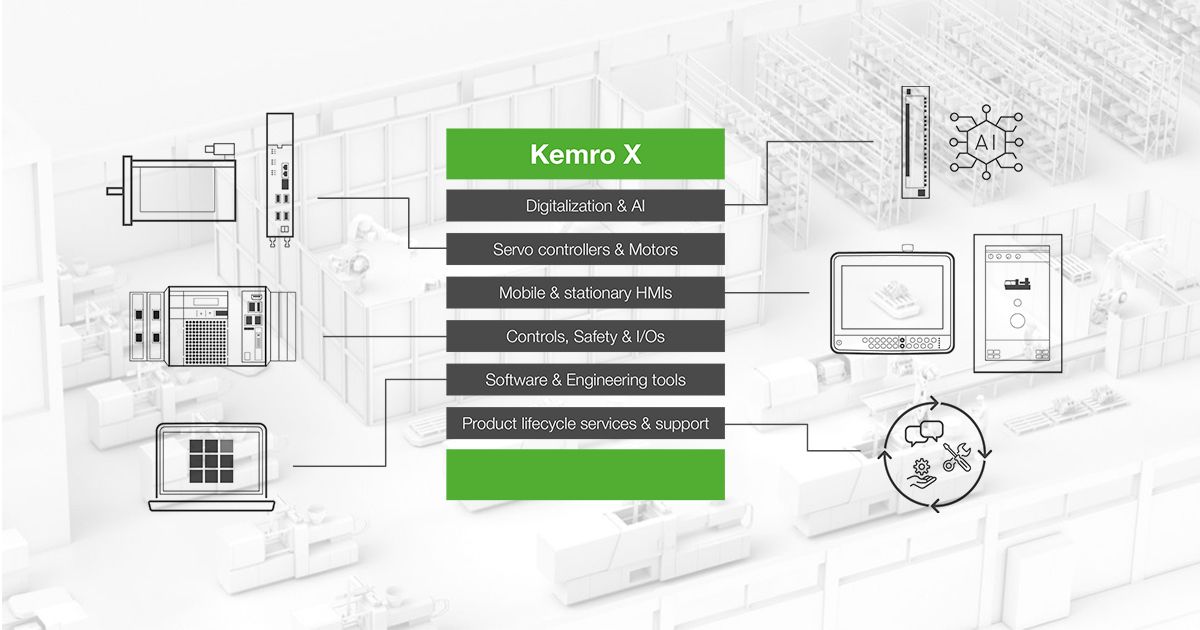

Kemro X is a modular automation platform consisting of apps, software, hardware, and technology packages. This makes it versatile and usable in many industries. The platform really shows its strengths in areas where machines need to be operated flexibly and efficiently.

Kemro X is particularly suitable for machine builders who develop series machines with a high degree of reuse and want to efficiently automate their engineering and service processes. The platform shows its strengths wherever recurring processes, standardized workflows, and fast commissioning are crucial.

Series machine builders in particular benefit enormously from Kemro X, as development, testing, commissioning, and service can be significantly automated. The open architecture, preconfigured functions, and proven interfaces are the result of decades of collaboration with leading machine building companies – enabling a noticeable reduction in engineering effort and a significant acceleration of projects.

Thanks to these proven features, Kemro X offers a high degree of standardization, reusability, and efficiency, making it the ideal automation platform for modern, competitive machine concepts.

What do I need to automate a machine?

A typical automation system consists of:

- Control

- I/O modules

- HMI

- (Servo) drives

- Safety components

Kemro X ensures that all automation components communicate seamlessly with each other, can be easily diagnosed, and can be efficiently parameterized and programmed. Optimized communication between the controller, I/O, drives, and other system components not only increases machine stability but also reduces the susceptibility to errors during operation.

The integrated diagnostic functions enable fast and precise fault analysis – a decisive advantage for developers, commissioning engineers, and service personnel. At the same time, uniform parameterization and programming greatly simplify the engineering process.

This significantly reduces the amount of engineering time required, increases the reusability of software and machine functions, and improves the total cost of ownership (TCO) in the long term.

Kemro X thus provides machine builders with optimal support in achieving more efficient processes, shorter development cycles, and more economical machines in the long term.

Why is the TCO of Kemro X especially attractive?

Many companies only consider hardware and licensing costs.

However, the real savings potential lies in:

- Faster configuration of each individual machine

- Reduced testing and update effort

- Consistent diagnostics

- Shorter training times

- Lower susceptibility to errors

- Higher software reuse

These factors are often underestimated. They lead to faster processes, higher quality, and better economic results. Less qualified personnel are also required.

In which industries and applications is Kemro X particularly strong?

Kemro X is suitable for many industries, especially for machines with dynamic, precise servo movements.

Typical areas of application:

- Plastics industry

- Robotics & integrated robot systems

- Sheet metal working

- Intralogistics

- Machine tools

Thanks to many years of cooperation with leading manufacturers:

- Initial commissioning is possible within a few days

- Development and service processes are highly optimized

- Robots can be used particularly efficiently as machine components

When is Kemro X not the right solution?

Kemro X is less suitable for:

- Process automation

- Building automation

- Mobile automation

Specific standards, certificates, or special technical requirements (e.g., extreme cable lengths) are crucial here.

Kemro X is also not suitable if a Windows IPC is required as the main controller. However, Windows can be used for HMIs without any problems.

Kemro X thus provides machine builders with optimal support in achieving more efficient processes, shorter development cycles, and more economical machines in the long term.

Does Kemro X fit into existing machine concepts?

Yes. The platform is open and allows for easy integration of:

- your own software modules

- specific sensors

- safety-related components

- hydraulic or pneumatic elements

If you no longer want to maintain operating systems, hardware interactions, or automation apps yourself, Kemro X offers an efficient platform solution. Standards such as C++, POSIX, and Linux make reuse extremely easy.

What is the best way for a mechanical engineer to get started with Kemro X?

The first steps:

- Define “jobs to be done”

- Joint analysis of machine and system design

- Create hardware and software architecture

- Define interfaces to third-party providers

- Set up a joint project team

- Set up source code management and automated testing

This creates a stable basis for reliable series machines.

Does KEBA offer support throughout the entire life cycle?

Yes – KEBA provides its customers with comprehensive support in the following areas:

- Consulting & system design

- Installation & commissioning

- Series support

- Training

- Software updates

- Remote & on-site service

- Replacement devices & lifecycle support

Conclusion: Who really benefits from Kemro X?

KEBA's Kemro X is particularly suitable for machine builders who have high demands on dynamics, precision, reusability, and efficiency in automation.

In short: Customers who develop series machines and want to optimize their engineering processes benefit the most.

Kemro X is ideal for machine builders who:

- build dynamic, precise servo machines

- need standardized engineering processes

- want to reuse software

- want to reduce TCO in the long term

- are looking for a flexible, open platform instead of isolated solutions

We have a long tradition of working closely with machine manufacturers – often over many years and product generations.

Among other things, this means:

- Co-engineering: Joint development of machine functions and architectures

- Joint project teams for design, implementation, and series support

- Open exchange: Requirements are incorporated directly into product development

- Long-term stability through reliable roadmaps